Exhaust system shops specialize in custom fabrication, transforming standard components into tailored solutions for enhanced performance or unique aesthetics. Clients share their visions, and experts collaborate using advanced CAD design, precision manufacturing, and skilled assembly to meet—and often exceed—expectations. This meticulous process yields high-performance exhaust systems with distinctive, personalized looks, appealing to car enthusiasts seeking bespoke upgrades. Despite longer lead times, growing demand reflects the allure of custom fabrication for high-performance automotive enhancements.

“Exhaust system shops are more than just places for routine maintenance; they’ve evolved into hubs of custom fabrication artistry. This article delves into the intricate process and creative science behind modifying exhaust systems, exploring how dedicated shops transform ideas into tailored, high-performance solutions.

From initial consultation to final installation, we’ll uncover the steps involved in custom fabrication, highlighting the benefits that make these modifications a popular choice among car enthusiasts.”

- Understanding Custom Fabrication: The Art and Science Behind Exhaust System Mods

- The Process: From Concept to Creation within Exhaust System Shops

- Benefits and Challenges: Why Custom Fabrication is a Popular Choice for Car Enthusiasts

Understanding Custom Fabrication: The Art and Science Behind Exhaust System Mods

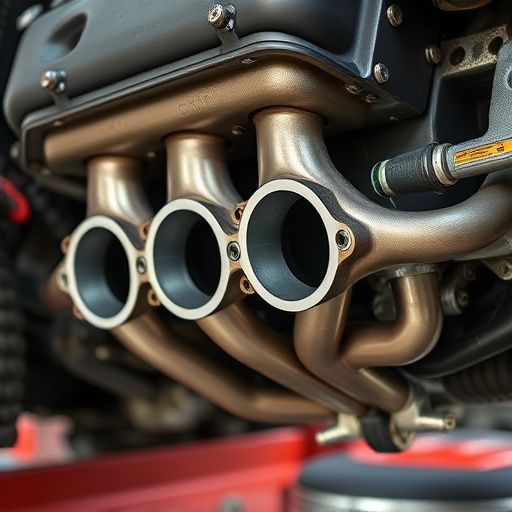

Custom fabrication is an artform practiced by skilled exhaust system shops, involving precise engineering and meticulous craftsmanship. It’s a process that transforms standard automotive components into tailored solutions designed to enhance performance or achieve unique aesthetics. At its core, custom fabrication requires a deep understanding of vehicle dynamics, materials science, and the ability to translate creative visions into functional reality.

Exhaust system shops specializing in this field often work with clients who seek specific modifications like installing coilover kits for precise suspension control or crafting custom air intake systems for optimized fuel efficiency. By combining cutting-edge technology and traditional craftsmanship, these shops can create exhaust systems that not only meet but exceed expectations, offering both enhanced performance and a distinctive look that sets the vehicle apart on the road.

The Process: From Concept to Creation within Exhaust System Shops

In an exhaust system shop, the journey from concept to creation is a meticulously crafted process, driven by a blend of technical expertise and customer vision. It all begins with the client presenting their idea or specific performance requirements. For example, they might seek improved engine sound, enhanced power output, or a unique visual appeal. The exhaust system specialists then collaborate closely with the client, offering guidance and suggestions while interpreting their needs into actionable plans.

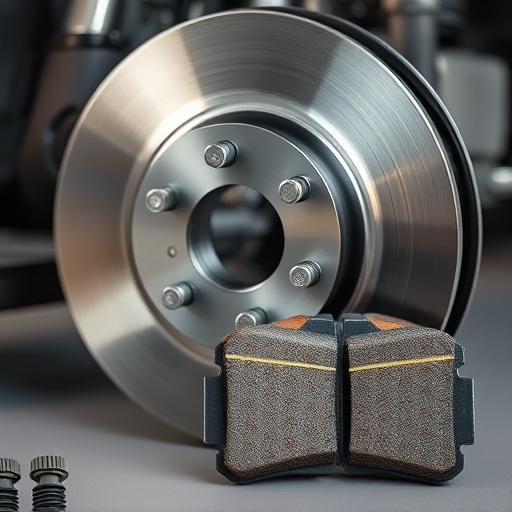

This collaborative phase involves detailed discussions about the desired outcome, including considerations like vehicle make and model compatibility, legal emission standards, and the integration of complementary components such as performance brakes or custom air filter kits. Once a clear vision is established, skilled artisans and engineers set to work, utilizing advanced machinery and computer-aided design (CAD) software to fabricate tailored parts. From precision cutting and welding to intricate assembly, every step ensures that the final product meets or exceeds expectations, transforming abstract concepts into tangible, high-performance exhaust systems ready for installation.

Benefits and Challenges: Why Custom Fabrication is a Popular Choice for Car Enthusiasts

For car enthusiasts looking to elevate their vehicle’s performance and aesthetics, custom fabrication offers a unique and personalized experience that sets them apart from mass-produced aftermarket parts. The appeal lies in the ability to tailor-fit components to specific requirements, ensuring optimal performance and a one-of-a-kind look. Exhaust system shops at the forefront of this trend often provide specialized services for custom fabricating various automotive parts, including exhaust systems, intake systems, and suspension upgrades like coilover kits.

While custom fabrication brings numerous advantages such as enhanced engine efficiency, improved styling, and a sense of individuality, it also presents challenges. It requires skilled artisans and advanced machinery to interpret the design vision into reality while adhering to strict safety standards. Moreover, the time-intensive nature of the process can result in longer lead times compared to readily available off-the-shelf products, like cat-back exhaust systems or air intake systems. Despite these challenges, the demand for custom fabrication continues to grow, driven by the desire for unique and high-performance automotive enhancements.

Exhaust system shops have mastered the art of custom fabrication, offering car enthusiasts unique solutions that enhance their vehicles’ performance and aesthetics. Through meticulous planning, skilled craftsmanship, and a deep understanding of automotive engineering, these shops transform ideas into reality. Custom fabrication not only allows for personalized modifications but also addresses specific needs, ensuring optimal engine efficiency and distinctive style. Despite the challenges involved, the benefits—from improved vehicle dynamics to exclusive design elements—make it a popular choice among car lovers seeking to stand out from the crowd.