Fast DTF Transfers are transforming manufacturing by offering swift, precise printing solutions that boost efficiency across diverse sectors. Eliminating traditional methods, these transfers enable high-quality, customizable production at rapid speeds, from apparel to 3D printing and electronics assembly. They streamline operations for small businesses and large manufacturers alike, accelerating product development cycles and adapting to market demands.

Advanced Applications of Fast DTF Transfers Today, we explore the transformative power of Fast DTF Transfers across diverse sectors. From revolutionizing manufacturing processes with enhanced rapid prototyping and small-batch production to transforming healthcare through expedited material delivery for improved patient care, these transfers are pushing boundaries in materials science and research. Discover how fast, efficient material handling is driving innovation, from 3D printing and electronics assembly to cutting-edge pharmaceutical distribution and personalized medicine.

- Revolutionizing Manufacturing Processes with Fast DTF Transfers

- – Exploring the impact on rapid prototyping and small-batch production

- – Case studies: 3D printing, electronics assembly, and precision engineering

Revolutionizing Manufacturing Processes with Fast DTF Transfers

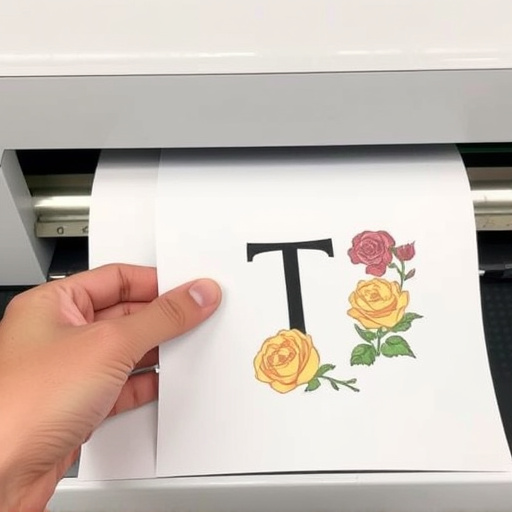

In today’s competitive manufacturing landscape, revolutionizing processes to enhance efficiency and productivity is paramount. Fast DTF (Direct-to-Fabric) Transfers have emerged as a game-changer, enabling manufacturers to streamline their operations and deliver high-quality products at a rapid pace. This cutting-edge technology facilitates the precise application of designs onto various fabrics, from bulk DTF shirt production to intricate custom DTF transfers. By eliminating traditional printing methods’ time-consuming steps, Fast DTF Transfers significantly reduce production cycles, allowing manufacturers to meet the ever-increasing demands of the market promptly.

The integration of fast DTF transfer sheets has not only simplified the design-to-product transformation but also opened doors for unparalleled customization. Manufacturers can now effortlessly create unique, personalized garments and products, catering to diverse consumer preferences. This versatility extends beyond clothing, as Fast DTF Transfers find applications in numerous industries, from accessories and home textiles to promotional items, marking a new era of speed, precision, and endless creative possibilities in manufacturing.

– Exploring the impact on rapid prototyping and small-batch production

The integration of Fast DTF Transfers has had a profound impact on rapid prototyping and small-batch production, revolutionizing the way products are developed and manufactured. This technology allows for swift and precise printing on various materials, enabling designers and engineers to swiftly bring their concepts to life. With DTF (Direct to Fabric) transfer sheets, the process of applying graphics and text to fabrics becomes incredibly efficient, making it ideal for DTG (Direct to Garment) printing in the apparel industry.

For small businesses and startups, Fast DTF Transfers offer a cost-effective solution for producing limited-edition items or custom designs. It streamlines production, reducing lead times significantly. This speed is particularly valuable when launching new product lines or meeting urgent market demands, ensuring that manufacturers can swiftly adapt to changing trends and consumer preferences.

– Case studies: 3D printing, electronics assembly, and precision engineering

The advanced applications of Fast DTF Transfers are transforming various industries. One notable area is 3D printing, where DTF transfers enable the creation of intricate and complex geometries with unparalleled accuracy. This technology allows for rapid prototyping and manufacturing, significantly reducing production times and costs in fields like automotive and aerospace.

Another crucial sector is electronics assembly, where DTF printers play a pivotal role. By facilitating precise placement of electronic components, these printers enhance product quality and yield. In precision engineering, DTF transfers are used to create highly detailed parts for medical devices, optical systems, and other specialized applications. This level of detail and accuracy ensures that final products meet the strictest standards, opening doors to innovative solutions in healthcare, technology, and beyond.

Fast DTF Transfers are transforming various industries by streamlining manufacturing processes. Their ability to facilitate rapid prototyping, small-batch production, and complex assembly, as evidenced in 3D printing, electronics, and precision engineering, makes them a game-changer in today’s competitive market. As these technologies continue to evolve, we can expect even more innovative applications of Fast DTF Transfers, revolutionizing the way products are designed, produced, and delivered.