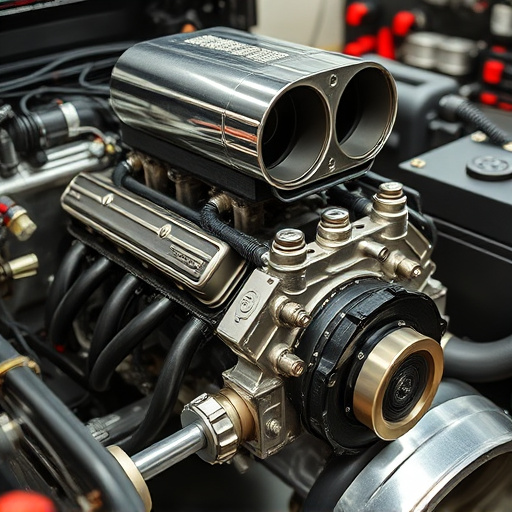

Gas and diesel engines differ primarily in their fuel systems and combustion processes. Gas engines use spark plugs for controlled explosions, enabling higher rotation speeds and instant torque, while diesel engines rely on compression ignition, creating powerful but slower combustion. These differences impact the design of engine components such as pistons, cylinders, and exhaust mufflers. Gas engines employ air-intake based metering with throttle control, often boosted by cold air intakes, whereas diesel engines use high-pressure fuel injectors for precise mixture control and increased power output. Proper maintenance requires understanding these distinctions to maximize lifespan and efficiency of engine components in each type of engine.

Explore the intricate differences between gas and diesel engine components in this comprehensive guide. From fuel systems and combustion processes, where we delve into the contrast between spark-ignition and compression-ignition, to engine design variations like inline, V, and boxer layouts. We also dissect exhaust systems and emission controls, revealing variations in pollution levels and the technologies employed for cleaner outputs. Understanding these disparities is key for informed decisions when choosing between these powerful machines.

- Fuel Systems and Combustion Processes

- – Comparison of fuel injection systems in gas and diesel engines

- – Differences in combustion processes: Spark-ignition vs. Compression-ignition

Fuel Systems and Combustion Processes

The heart of any internal combustion engine lies in its fuel system and combustion process. Gas engines typically employ a more sophisticated fuel injection system, which precisely meters and injects fuel into the air intake system. This method ensures a clean and efficient burn, as the fuel is mixed with air before entering the cylinder. In contrast, diesel engines rely on compression ignition, where highly compressed air heats up and ignites the fuel, usually in the form of diesel oil.

The combustion process itself differs significantly between gas and diesel engines. Gas engines ignite the fuel-air mixture using a spark plug, leading to a controlled explosion that drives the piston. This results in higher rotation speeds and more instant torque. Diesel engines, on the other hand, rely on the heat generated by compression to ignite the diesel fuel, creating a powerful but slower combustion process. This difference is reflected in the engine components, such as pistons, cylinders, and exhaust mufflers, which are designed to accommodate these distinct operational characteristics.

– Comparison of fuel injection systems in gas and diesel engines

Gas and diesel engines differ significantly in their fuel injection systems. In gas-powered vehicles, the injection process involves metering fuel based on air intake, with a throttle valve controlling airflow. This system is often paired with a cold air intake for enhanced vehicle performance. On the other hand, diesel engines use high-pressure fuel injectors to directly spray fuel into the combustion chamber. This direct injection results in more precise control over fuel-air mixture, leading to better engine efficiency and power output.

Coilover kits, a popular modification for both types of engines, can further enhance engine components performance by allowing for adjustable suspension and improved shock absorption. However, the fundamental difference in fuel delivery methods means that adjustments to these systems may yield varying results depending on whether they are gas or diesel powered vehicles.

– Differences in combustion processes: Spark-ignition vs. Compression-ignition

The combustion process is a fundamental aspect that differentiates gas and diesel engines, impacting their overall design and performance. Gas engines, also known as spark-ignition engines, rely on a spark plug to ignite the air-fuel mixture within the cylinder. This type of engine is commonly found in vehicles with gasoline engines, where a precise timing of the spark is crucial for efficient combustion. On the other hand, diesel engines utilize compression ignition, where highly compressed air heats up and ignites the fuel automatically as it enters the cylinder. This process allows diesel engines to have higher thermal efficiency compared to their gas counterparts.

These variations in combustion lead to distinct engine component requirements. For instance, gas engines often feature advanced ignition systems, precise fuel injection mechanisms, and high-performance air filters to ensure optimal air-fuel mixing and combustion. In contrast, diesel engines focus more on robust compression ratios, durable injectors for precise fuel distribution, and efficient exhaust systems that minimize emissions without compromising performance. Understanding these differences is essential when considering the maintenance and replacement of engine components, such as brake components, ensuring each engine type receives the appropriate care to maximize their operational lifespan and efficiency.

In understanding the differences between gas and diesel engine components, particularly focusing on fuel systems and combustion processes, it’s clear that these technologies cater to distinct needs. Gas engines rely on spark-ignition, featuring precise fuel injection systems for clean, efficient burning. Conversely, diesel engines employ compression-ignition, where high compression temperatures ignite fuel, resulting in robust power outputs. These variations significantly impact performance, fuel efficiency, and emission profiles, shaping the applications suited for each engine type across various industries, from automotive to heavy machinery.