Intercooler piping is a critical system in high-performance vehicles, comprising couplers, clamps, and bends that facilitate efficient cooling by strategically routing compressed air, securing pipes, and navigating around components. Installing and maintaining intercooler piping requires meticulous attention to detail, including compatibility checks, proper thread sizes, quality clamps, custom bends for tight spaces, and regular inspections for wear or damage. Regular maintenance ensures optimal airflow efficiency, contributing to overall vehicle performance.

Intercooler piping is a critical component in automotive cooling systems, ensuring optimal engine performance. This article delves into the essential elements that make up intercooler piping, focusing on couplers, clamps, and bends. We explore their roles in enhancing airflow and temperature control while discussing best practices for installation and maintenance to prevent leaks and ensure longevity. By understanding these components, you’ll be better equipped to maintain and optimize your vehicle’s cooling system, leveraging the power of efficient intercooler piping.

- Understanding Intercooler Piping Components

- The Role of Couplers, Clamps, and Bends

- Best Practices for Installation and Maintenance

Understanding Intercooler Piping Components

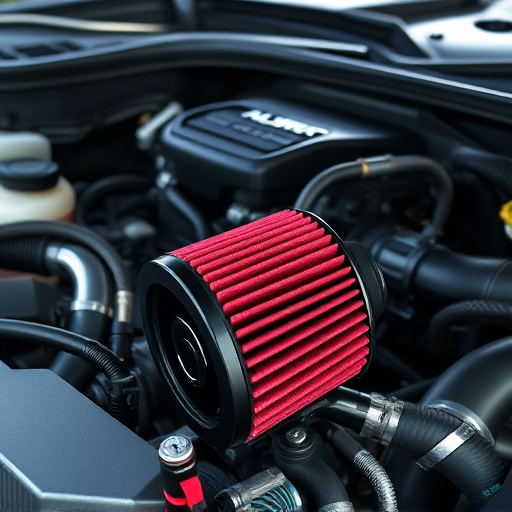

Intercooler piping is a crucial component in vehicle performance systems, especially for those seeking to enhance their car’s capabilities. Understanding the various parts that make up this system is essential when considering modifications. The primary elements include couplers, clamps, and bends, each playing a vital role in ensuring efficient cooling.

Couplers serve as connections between pipes, allowing for fluid flow while maintaining pressure. Clamps secure the piping in place, preventing leaks and ensuring stability. Bends, or turns, are engineered to navigate around various components within the vehicle, such as exhaust mufflers and coilover kits, without compromising airflow. These parts work harmoniously to optimize cooling efficiency, thereby improving overall vehicle performance.

The Role of Couplers, Clamps, and Bends

In the intricate world of intercooler piping, couplers, clamps, and bends play a pivotal role in ensuring optimal performance and efficiency. These components form the backbone of the cooling system, facilitating the seamless flow of compressed air within the intercooler assembly. Couplers, in particular, serve as the connectors that join pipes together, allowing for strategic routing and tailoring of the airflow to match specific vehicle requirements.

Clamps, on the other hand, are crucial for secure mounting and holding pipes in place, preventing any potential shifting or disconnection. They offer a reliable means of fastening, especially in high-pressure environments where leakages can be detrimental. Additionally, bends in intercooler piping allow for precise adjustments to air flow direction, enabling installation in challenging spaces and enhancing overall system flexibility—a valuable aspect when integrating performance air filters or coilover kits as part of suspension upgrades.

Best Practices for Installation and Maintenance

When installing intercooler piping, proper techniques are paramount to ensure optimal vehicle performance and longevity. Start by ensuring all components, including couplers, clamps, and bends, are compatible with your vehicle’s system. Double-check thread sizes and pipe diameters to avoid leaks. Use high-quality clamps that provide a secure fit without damaging the pipes. For tight spaces, consider custom bends to maintain efficient airflow without compromising the intercooler’s cooling capacity.

Regular maintenance is key to keeping your intercooler piping in top condition. Inspect the system for signs of wear, corrosion, or damage at regular intervals. Replace any worn-out components promptly, such as clamps or seals. Keep an eye on brake rotors and coilover kits, as these can be affected by heat buildup from the intercooler. Regular cleaning of the pipes and couplers helps maintain airflow efficiency, contributing to overall vehicle performance.

Intercooler piping, comprised of couplers, clamps, and bends, is a crucial component in enhancing engine performance. By understanding these essential parts and implementing best practices during installation and maintenance, you can ensure optimal cooling efficiency. Effective management of intercooler piping not only improves engine longevity but also maximizes the overall performance of your vehicle, making it a critical aspect to consider for any automotive enthusiast or professional mechanic.