Electronic Exhaust Cutout (EEC) systems in modern vehicles offer customizable sounds and improved performance, but face challenges like faulty sensors, drivability issues, and component wear from high temperatures. Regular maintenance, including visual inspections and preventative checks, is crucial. Replace malfunctioning sensors and repair/replace defective muffler tips or exhaust components. For complex cat-back system problems, consult a professional mechanic. Use high-quality industry-standard parts, ensure proper integration with vehicle systems, and adhere to manufacturer guidelines for optimal EEC performance, reliability, and reduced maintenance headaches.

Electronic exhaust cutouts are essential components in modern vehicles, managing engine emissions and improving performance. However, these systems can encounter issues, leading to reduced efficiency and potential damage. This article delves into the common problems plaguing electronic exhaust cutouts, from sensor malfunctions to clogging and leakage. We offer practical solutions and preventative measures for reliable operation, focusing on key aspects like regular maintenance, high-quality parts, and expert installation. Understanding these fixes is crucial for optimal vehicle health and environmental compliance.

- Understanding Electronic Exhaust Cutouts: Their Function and Common Problems

- Identifying and Resolving Frequent Issues with Exhaust Cutout Systems

- Preventative Measures and Best Practices for Reliable Electronic Exhaust Cutouts

Understanding Electronic Exhaust Cutouts: Their Function and Common Problems

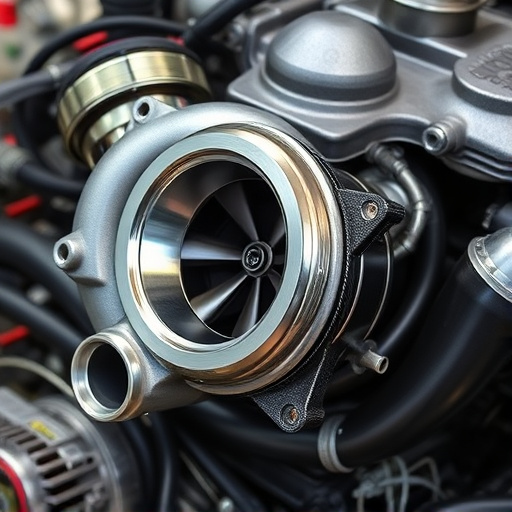

Electronic exhaust cutouts have become a popular feature in modern vehicles, offering precise control over engine sound and performance. They work by electronically adjusting the flow of exhaust gases, allowing for customizable exhaust notes and enhanced vehicle dynamics. However, like any complex system, electronic exhaust cutouts are susceptible to several issues that can impact their performance and reliability.

Some common problems include faulty sensors leading to incorrect adjustment of the cutout valves, resulting in unusual sound patterns or even drivability concerns. Over time, the components within the cutout assembly may wear out, particularly if subjected to high temperatures and pressure from a modified cat-back exhaust system. This can cause coilover kits designed for fine-tuning ride height to interact unpredictably with the dynamic exhaust system, affecting overall vehicle handling. Regular maintenance and using high-quality parts are key to mitigating these issues and ensuring optimal performance of electronic exhaust cutouts.

Identifying and Resolving Frequent Issues with Exhaust Cutout Systems

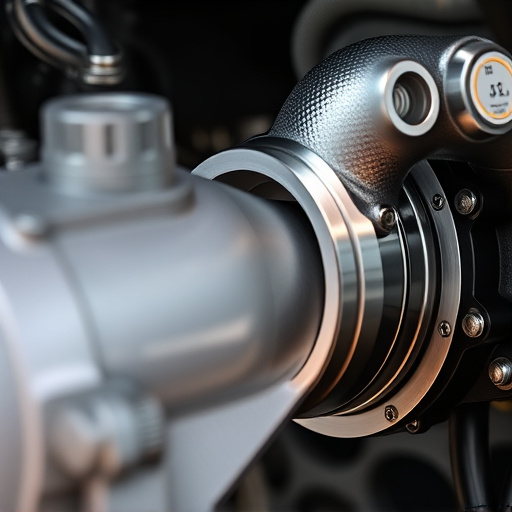

Identifying issues with electronic exhaust cutout systems is crucial for maintaining optimal vehicle performance and minimizing maintenance headaches. Frequent problems include malfunctioning sensors, defective actuators, or misalignment of cutout doors. Regular visual inspections can reveal signs like leaks, corrosion, or damage to these components. If a sensor is suspected to be faulty, replacing it with a new one from a reputable supplier is often the solution.

When addressing muffler tips or exhaust mufflers that are not functioning properly, checking for obstructions, corroded parts, or incorrect installations is essential. In many cases, cleaning or replacing these components can resolve issues related to reduced engine performance or unusual noises. For more complex problems with cat-back exhaust systems, consulting a professional mechanic is advisable. They can diagnose and fix issues like disconnected pipes, faulty joints, or blockages that may hinder exhaust flow and cause the cutout system to malfunction.

Preventative Measures and Best Practices for Reliable Electronic Exhaust Cutouts

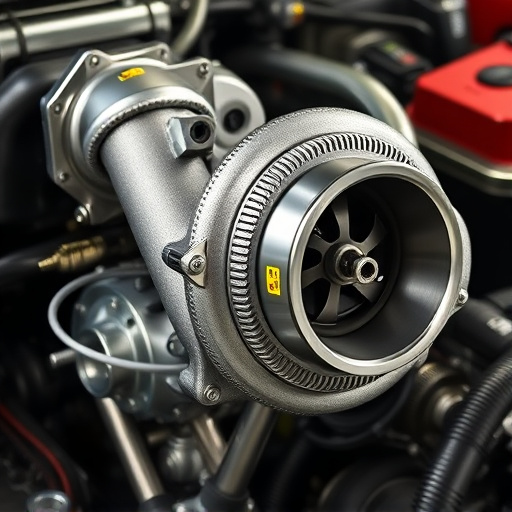

To ensure reliable operation and longevity of electronic exhaust cutouts (EECs), preventative measures and best practices should be implemented. Regular maintenance checks are crucial, including inspecting connections for any signs of damage or corrosion, as well as verifying proper grounding to mitigate electrical faults. Upgrading to high-quality, industry-standard EEC components can significantly reduce failure rates. This includes using robust wiring harnesses and connectors designed to withstand environmental stressors.

Additionally, integrating EECs seamlessly with other vehicle systems, such as cold air intakes (CAIs) and exhaust mufflers, is essential. Ensuring compatibility and proper integration minimizes the risk of performance issues or system malfunctions. Best practices also involve adhering to manufacturer guidelines for installation, including specified torque settings and proper alignment. By combining these preventative measures, you can foster reliable operation, enhance overall vehicle performance, and extend the lifespan of your electronic exhaust cutouts.

Electronic exhaust cutouts are integral to modern vehicle systems, offering enhanced performance and efficiency. However, like any complex component, they can encounter issues. By understanding the common problems and implementing preventative measures, such as regular maintenance and using high-quality parts, vehicle owners can ensure reliable operation of their electronic exhaust cutout systems. Regularly addressing these challenges will contribute to a smoother driving experience and extend the lifespan of your vehicle’s vital components.