Direct-to-Film (DTF) Transfers revolutionize product design and marketing by enabling brands to create intricate, vibrant designs directly on various materials with unmatched precision. This technology streamlines production, offering fast turnaround times and reducing costs, especially for startups. DTF eliminates traditional printing complexities, allowing brands to swiftly adapt marketing strategies and maintain consistent branding in a competitive market. Its versatility and efficiency make it ideal for custom merchandise production, from bulk DTF shirt printing to limited-edition items, ensuring products remain fresh and relevant.

In today’s fast-paced market, brands constantly seek innovative strategies to elevate their product offerings. One such game-changer is embracing Direct-to-Film Transfers (DTF), a modern branding advantage that’s revolutionizing production. This article delves into the world of DTF transfers, exploring why they’re becoming a popular choice for many businesses. From cost and time efficiency to enhanced quality and streamlined innovation, understanding this technology offers valuable insights for brands looking to stay ahead in the competitive landscape.

- Understanding Direct-to-Film Transfers: A Modern Branding Advantage

- The Benefits for Brands: Cost, Time, and Quality Efficiency

- Streamlining Production: How DTF Transfers Enhance Product Innovation

Understanding Direct-to-Film Transfers: A Modern Branding Advantage

Direct-to-Film Transfers (DTF) represent a cutting-edge technology that has revolutionized branding and product design. This innovative process allows brands to create intricate, high-quality designs directly on various materials, including fabrics. Unlike traditional printing methods, DTF offers unparalleled precision and vibrancy, enabling the reproduction of complex artwork with remarkable detail. By eliminating the need for intermediate steps, brands can achieve fast production times without compromising on visual appeal.

For product marketing, this modern advantage is significant. DTF facilitates the efficient production of custom merchandise, such as bulk DFT shirt production, where intricate graphics and detailed designs can be effortlessly applied to garments. This technology empowers businesses to stay agile and responsive to market trends, swiftly launching promotional campaigns and creating unique branded items that stand out in a crowded marketplace. The versatility of DTF transfers extends beyond clothing, applicable across diverse products, ensuring brands have a versatile tool for creative expression.

The Benefits for Brands: Cost, Time, and Quality Efficiency

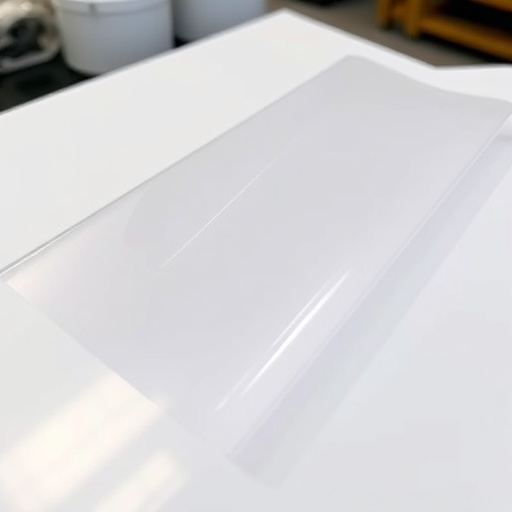

Direct-to-Film Transfers (DTF) offer brands an efficient and cost-effective solution for product promotion. By skipping traditional printing methods, brands can significantly reduce production costs, making it an attractive option for small businesses or startups with tight budgets. This process eliminates the need for complex set-ups and equipment, streamlining the entire production line.

Moreover, DTF transfers save time from start to finish. From design to final product, the direct transfer method accelerates the manufacturing process. Brands can swiftly adapt their marketing strategies by quickly producing custom prints on various materials, ensuring they stay agile in a dynamic market. With high-quality results, brands can maintain consistent messaging and branding while offering unique, personalized products to their customers, all achieved with remarkable efficiency.

Streamlining Production: How DTF Transfers Enhance Product Innovation

Direct-to-Film (DTF) Transfers have revolutionized product innovation by streamlining production processes. This cutting-edge technology allows brands to create custom designs and bring them to life swiftly, eliminating traditional printing methods that often involve lengthy lead times. With DTF transfers, brands can easily adapt to market trends and customer preferences, ensuring their products stay fresh and relevant.

The efficiency of DTF transfers lies in their ability to directly print onto various materials, such as fabric, plastic, or metal, without the need for intermediate steps. This direct approach eliminates potential issues like misalignment or poor quality that can arise from traditional printing methods. Moreover, custom dtf transfers offer brands unparalleled flexibility, enabling them to produce limited-edition items or personalized products on demand, all while maintaining high-quality standards and consistent branding.

Direct-to-Film Transfers (DTF) have emerged as a powerful tool for brands seeking to streamline their production processes and enhance product innovation. By leveraging DTF technology, companies can achieve significant cost savings, reduce time-to-market, and maintain high-quality standards. This modern branding advantage allows businesses to stay agile in a competitive market, ultimately fostering faster and more efficient product development cycles.