A power stop brake kit enhances a vehicle's braking by focusing on rotors and pads. Rotors, made from cast iron or aluminum, provide a smooth surface for heat transfer during braking. Brake pads vary in materials, offering traits like durability (organic/semi-metallic) or quieter braking (low-dampening). Solid and vented rotor types are available, with solid rotors dissipating heat evenly and vented rotors improving airflow for heavy braking events. Choosing the right pad depends on driving needs: racing or off-road drivers need high-performance pads, while daily commuters prefer longer-lasting ones. Always consider vehicle requirements and consult experts for optimal performance, safety, and compatibility.

“Enhance your vehicle’s braking performance with a comprehensive look at Power Stop brake kit components. This article guides you through the core elements, focusing on rotors and pads—essential for optimal stopping power. We’ll explore the distinction between solid and vented rotors, each offering unique advantages. Additionally, we’ll delve into choosing the right brake pads tailored to your vehicle’s needs, balancing performance and durability. Maximize your Power Stop brake kit’s potential with this insightful comparison.”

- Understanding Power Stop Brake Kit Components: Rotors and Pads

- Types of Brake Rotor Materials: Solid vs. Vented

- Choosing the Right Brake Pad for Your Vehicle: Performance and Durability Considerations

Understanding Power Stop Brake Kit Components: Rotors and Pads

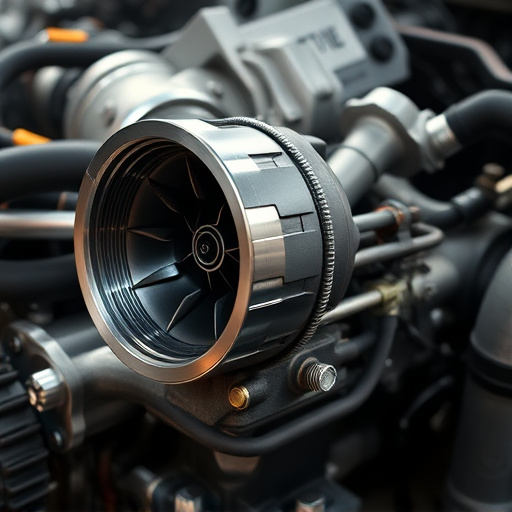

A power stop brake kit is a comprehensive assembly designed to enhance your vehicle’s braking performance, offering better stopping power and control. At the heart of this upgrade lie two primary components: rotors and pads. The rotor, often made from cast iron or aluminum, serves as the rotating part of the brake system, attached to the wheel hub. Its smooth surface comes into contact with the brake pad during the braking process, transforming kinetic energy into heat.

Brake pads, on the other hand, are stationary components that make direct contact with the rotor. They come in various types and materials, each offering distinct performance characteristics. Some power stop brake kit options prioritize durability and heat dissipation, using high-quality materials like organic or semi-metallic compounds. Others focus on reduced noise and smoother braking, employing low-dampening materials. Understanding these components’ roles is key to selecting the ideal power stop brake kit that aligns with your driving needs and preferences, enhancing both safety and performance.

Types of Brake Rotor Materials: Solid vs. Vented

Brake rotors are a critical component of any power stop brake kit, and their design can significantly impact braking performance. The two primary types of rotor materials are solid and vented. Solid rotors are uniform in composition, typically made from cast iron or steel, offering consistent heat dissipation throughout the disc. This design choice is common in many standard vehicle applications, focusing on cost-effectiveness and reliable braking power for everyday driving conditions.

Vented rotors, on the other hand, feature a series of cooling vents that enhance airflow, allowing for more efficient heat transfer during heavy braking events. This design is particularly advantageous in high-performance vehicles or those with demanding driving styles. By improving heat management, vented rotors can reduce brake fade, ensuring consistent and powerful stopping capabilities, even under extreme conditions. This is especially beneficial when considering the impact of intake components, exhaust mufflers, and overall vehicle performance.

Choosing the Right Brake Pad for Your Vehicle: Performance and Durability Considerations

When selecting brake pads for your vehicle, it’s crucial to consider both performance and durability. Different vehicles have distinct needs based on factors like driving style, weight, and intended use. For instance, if you’re a racing enthusiast or frequently drive in rugged terrain, high-performance pads designed for aggressive stopping power might be the ideal choice. These pads offer superior heat dissipation and enhanced friction, ensuring precise control under extreme conditions.

On the other hand, daily commuters may opt for more balanced options that prioritize longevity. Look for pads with consistent wear patterns and materials engineered to resist warping or corrosion. Remember, top-tier power stop brake kits often come with a variety of pad types catering to various driving profiles. Consider consulting your vehicle’s owner manual or seeking advice from experts to make an informed decision, ensuring optimal performance and safety while factoring in the specific requirements of your air intake systems and intake components, as well as overall brake components.

When selecting a Power Stop Brake Kit, understanding the interplay between rotors and pads is key. Whether choosing solid or vented rotors, and high-performance or standard pads, your decision should align with your vehicle’s needs—considering both stopping power and longevity. By thoughtfully matching rotor and pad materials, you can enhance your braking experience, ensuring a safe and smooth ride for years to come.