The DTF Cold Peel Film revolutionizes print and design in textiles, offering enhanced edge clarity and precise lines via its innovative 'Cold Peel' technology. Ideal for custom apparel creation and craft projects, this film acts as a temporary carrier for designs, allowing easy application and removal without compromising details or fine lines. Its benefits include faster production times, high-quality prints, durability, and vibrant colors even after multiple washes, transforming direct to film printing and ensuring outstanding edge clarity. Best practices for implementation include preparing clean print surfaces, using precision tools, adhering to manufacturer setting times, and employing high-quality printers and OEM films.

Discover how DTF Cold Peel Film is transforming the way we achieve edge clarity and sharp lines in various applications. This innovative technology offers a precise and efficient solution, revolutionizing the market. By understanding its underlying principles, you’ll unlock the benefits it brings, from enhanced visual appeal to improved production efficiency. Learn best practices for implementation to maximize results and explore why DTF Cold Peel Film is becoming an indispensable tool across industries.

- Understanding DTF Cold Peel Film Technology

- Benefits of Using DTF Cold Peel Film for Edge Clarity and Sharp Lines

- Implementation and Best Practices for Optimal Results

Understanding DTF Cold Peel Film Technology

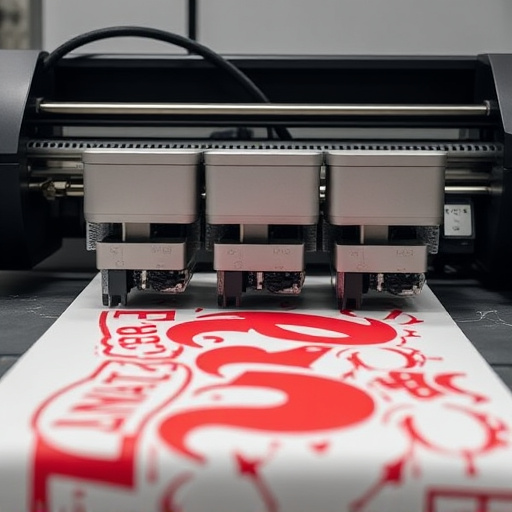

DTF Cold Peel Film is a cutting-edge technology that has revolutionized the world of print and design, particularly in the textile industry. This innovative film is designed to enhance the process of applying graphics and patterns to various materials, with a focus on improving edge clarity and achieving sharp, precise lines. The ‘Cold Peel’ feature sets it apart from traditional heat-application methods, making it a game-changer for both professional printers and DIY enthusiasts.

By using DTF (Direct-To-Film) transfer films, such as those designed for t-shirts and other fabrics, users can achieve superior results in their printing projects. The film acts as a temporary carrier for the design, allowing for easy application and removal. This technology ensures that intricate details and fine lines are not compromised during the transfer process, resulting in vibrant and crisp graphics on the final product. Whether it’s for creating custom apparel or enhancing craft projects, DTF printing offers a straightforward and effective solution, appealing to a wide range of creators and businesses alike.

Benefits of Using DTF Cold Peel Film for Edge Clarity and Sharp Lines

The DTF Cold Peel Film is a game-changer when it comes to enhancing edge clarity and achieving sharp lines in various applications, particularly in apparel and clothing design. This innovative film offers numerous advantages for printers and designers looking to elevate their work. One of its key benefits is its ability to provide precise control over the cutting process, resulting in clean and crisp edges on materials. The film’s unique properties allow for accurate reproduction of fine details and intricate patterns, ensuring that every design element is showcased flawlessly.

Using DTF for Apparel has revolutionized direct to film printing, enabling faster production times and higher quality outcomes. Its cold peel feature simplifies the removal process, saving time and effort compared to traditional methods. This makes it an ideal choice for rush orders or when quick turnaround times are essential. Additionally, the film’s durability guarantees that printed designs maintain their sharpness and vibrancy even after multiple washes, ensuring long-lasting impact for apparel brands.

Implementation and Best Practices for Optimal Results

The implementation of DTF Cold Peel Film is a game-changer for achieving crisp, clean edges and sharp lines in apparel printing. This innovative film offers a simple yet effective solution to enhance the overall quality of printed designs. To maximize its potential, follow these best practices for optimal results. Firstly, ensure your print surface is properly prepared; a clean, smooth substrate is key to achieving excellent adhesion of the DTF film.

When applying the film, use a precision tool or squeegee for an even, consistent coat. Allow the DTF to set according to the manufacturer’s instructions before peeling it off. For best results, consider using a high-quality DTF printer and original equipment manufacturer (OEM) films, as this ensures precise color reproduction and long-lasting durability. Remember that proper application techniques and the right materials will result in outstanding edge clarity, making your printed garments stand out.

The DTF Cold Peel Film technology offers a revolutionary approach to achieving crisp, precise edges in various industries. By utilizing this film, professionals can significantly enhance their work’s visual appeal and overall quality. With its ability to provide exceptional edge clarity and sharp lines, DTF Cold Peel Film is an innovative solution that streamlines processes and captivates audiences. Implement these practices to unlock the full potential of this game-changing material.