The performance of a vehicle's engine hinges on a complex network of engine components working in harmony. From intake components facilitating combustion to exhaust systems expelling waste gases, each part is vital for power generation and efficiency. Understanding these engine components enables drivers to make informed decisions about maintenance, upgrades, or repairs, ensuring optimal performance and longevity. In automotive engineering, recognizing the interconnectedness of parts allows for fine-tuning that enhances fuel efficiency, horsepower, and overall smoothness of operation.

Understanding the intricate relationship between engine components is key to unlocking optimal performance and efficiency. This comprehensive guide delves into the fundamental roles each component plays, exploring their interconnectedness as a complex system. From pistons to valve trains, every element contributes to the holistic function of the engine. By analyzing these relationships, we can optimize performance, enhance durability, and better appreciate the intricate dance of mechanical engineering that powers our vehicles.

- The Role of Engine Components: A Comprehensive Overview

- Interconnectedness: How Components Work Together

- Optimizing Performance through Component Relationships

The Role of Engine Components: A Comprehensive Overview

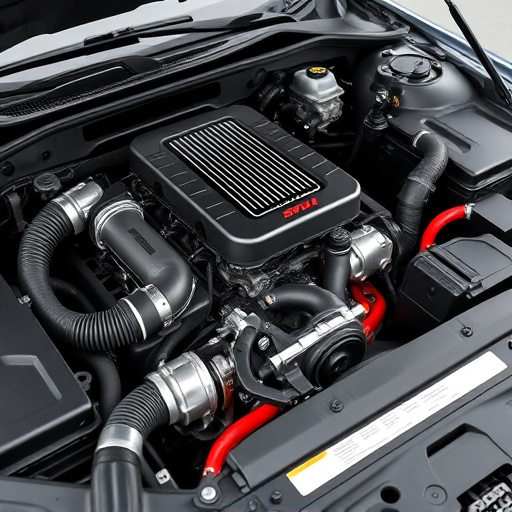

The engine is the heart of a vehicle, and its performance heavily relies on the seamless interaction of numerous engine components. Each part plays a critical role in ensuring smooth operation, power generation, and overall efficiency. From the intake components that draw in air and fuel to create combustion, to the exhaust tips that expel spent gases, every element contributes to the engine’s functionality.

The air filter kits, for instance, are vital for maintaining optimal airflow, preventing dirt and debris from entering the engine, thereby enhancing its longevity and performance. Understanding these engine components is essential for anyone aiming to optimize their vehicle’s performance or engage in basic maintenance. By recognizing the relationship between these parts, drivers can make informed decisions about regular service, upgrades, or repairs, ensuring their vehicles run efficiently and reliably.

Interconnectedness: How Components Work Together

The beauty of a car engine lies in its intricate dance of interconnected parts, where each component plays a vital role in ensuring smooth and efficient operation. Engine components, such as the cylinder block, pistons, valves, and camshaft, work in harmony to transform fuel and air into motion. The air filter kit, though often overlooked, is a crucial link in this chain; it ensures that only clean air enters the engine, optimizing combustion and power output.

Similarly, suspension components like shock absorbers and springs contribute to the overall performance and handling of the vehicle. When all these parts—from intake systems to exhaust systems, including performance exhaust setups—function together seamlessly, the result is a powerful, responsive engine that delivers exceptional performance. Understanding this interconnectedness is key to recognizing how small adjustments in one component can impact others, ultimately affecting the overall performance and longevity of the engine.

Optimizing Performance through Component Relationships

In the intricate world of automotive engineering, understanding the relationship between engine components is key to unlocking optimal performance. Each part, from the cylinder head to the spark plugs, plays a vital role in the complex dance of combustion and power generation. By appreciating these interconnections, engineers can fine-tune the engine’s capabilities, leading to improved fuel efficiency, increased horsepower, and smoother operation.

One significant aspect of this relationship involves the interplay between critical components like exhaust mufflers and suspension kits. While exhaust mufflers are responsible for reducing noise pollution, a well-tuned exhaust system can also enhance engine performance by optimizing gas flow. Similarly, suspension kits contribute to handling and stability, allowing for better cornering and control. Integrating high-performance parts, such as upgraded pistons or injectors, further strengthens the bond between these components, resulting in a more powerful, responsive, and efficient machine.

Understanding the intricate relationships between engine components is key to unlocking optimal performance and efficiency. By comprehending how each component interacts, from the crankshaft to the spark plugs, automotive engineers can make informed decisions to enhance power outputs while ensuring durability. This knowledge is especially vital in today’s advanced engines, where precision engineering and material science innovations push boundaries. With a deep grasp of engine components, mechanics and enthusiasts alike can navigate the complex landscape of vehicle dynamics, fostering continuous improvements in this ever-evolving industry.