Exhaust system shops face significant challenges from rust and corrosion, impacting vehicle performance and safety. Moisture, harsh weather, salt, chemicals, and acidic fumes accelerate corrosion in exhaust pipes, manifolds, and headers. Shops combat these issues through specialized coatings, sealing agents, regular maintenance, and expert knowledge, especially in coastal areas. By employing strategic measures like cleaning, protective coatings, high-quality parts, and inspections, exhaust system shops ensure the longevity and optimal performance of automotive exhaust systems.

In the world of automotive maintenance, exhaust system shops face a common challenge: addressing rust and corrosion. These issues not only compromise the performance of vehicles but also pose safety hazards. Understanding the underlying causes, such as exposure to harsh elements and improper maintenance, is crucial. This article explores effective strategies employed by exhaust system shops to tackle these problems, from material upgrades to advanced cleaning techniques, ensuring longer-lasting and safer exhaust systems for drivers.

- Understanding Rust and Corrosion in Exhaust Systems

- Common Causes and Risk Factors for Exhaust System Damage

- Effective Strategies Used by Exhaust System Shops to Combat Rust and Corrosion

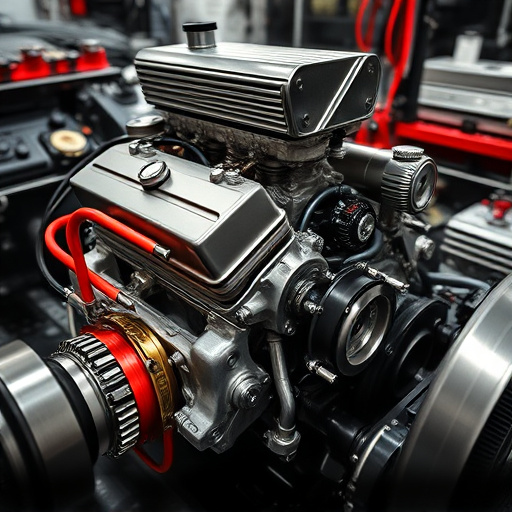

Understanding Rust and Corrosion in Exhaust Systems

Rust and corrosion are common enemies that every exhaust system shop faces head-on daily. These unwanted intruders can cause significant damage to vehicles’ exhaust components, leading to reduced performance and potentially unsafe driving conditions. Understanding the causes and impact of rust is essential for exhaust shops to provide effective solutions.

The primary culprits behind rust in exhaust systems are exposure to moisture and harsh environmental conditions. Over time, salt, chemicals, and acidic fumes from engine combustion can accelerate corrosion. Exhaust pipes, manifolds, and headers are particularly vulnerable areas due to their constant exposure to hot gases and external elements. In addition, vehicles operating in wet or corrosive environments, such as coastal regions or areas with salty road treatments, are at a higher risk of developing rust issues. Exhaust system shops employ various strategies, including specialized coatings, sealing agents, and regular maintenance, to prevent and mitigate corrosion, ensuring optimal vehicle performance and safety.

Common Causes and Risk Factors for Exhaust System Damage

Rust and corrosion are persistent issues that exhaust system shops frequently encounter. Several factors contribute to the deterioration of exhaust systems, making them a common problem for vehicles. One primary cause is prolonged exposure to moisture, especially in regions with high humidity or frequent rain. The damp environment accelerates rust formation on metal surfaces, including the exhaust pipes, mufflers, and suspension components. Over time, this can lead to structural weaknesses and cracks, compromising the integrity of the entire exhaust system.

Another significant risk factor is the lack of proper maintenance. Ignoring regular cleaning and inspection can result in a buildup of grease, dirt, and debris within the exhaust system. This obstruction not only reduces engine performance but also traps moisture, creating an ideal environment for rust to thrive. Furthermore, certain chemicals present in exhaust fumes can accelerate corrosion if not adequately sealed or protected by specialized coatings. Exhaust system shops play a vital role in mitigating these risks by offering expertise in rust prevention, repair, and maintenance services, ensuring the longevity of exhaust systems.

Effective Strategies Used by Exhaust System Shops to Combat Rust and Corrosion

Many exhaust system shops employ strategic measures to combat rust and corrosion, ensuring longevity and optimal performance in automotive exhaust systems. One effective approach is regular cleaning and maintenance. Shops often use specialized tools and solutions to remove built-up dirt, grease, and salt deposits that accelerate corrosion. Additionally, applying protective coatings and undercoating can create a barrier between metal surfaces and potential corrosive elements.

Another key strategy involves the use of high-quality components like performance air filters and exhaust mufflers designed with rust-resistant materials. These parts are built to withstand harsh environmental conditions, reducing the risk of corrosion over time. Furthermore, exhaust system shops may recommend periodic inspections and replacement of vulnerable parts, such as air filter kits, to minimize damage caused by moisture intrusion and debris buildup.

Exhaust system shops employ a variety of effective strategies to combat rust and corrosion, including regular maintenance, high-quality materials, and advanced repair techniques. By understanding the common causes of damage and implementing robust preventive measures, these shops ensure that vehicles remain safe, efficient, and environmentally compliant. Choosing an exhaust system shop that prioritizes these efforts can significantly extend the lifespan of your exhaust system, safeguarding both your vehicle’s performance and the health of our planet.