Electronic Exhaust Cutouts (EECs) are advanced emission control systems subject to stringent regulations, aiming to reduce pollutants like NOx and particulate matter. Manufacturers must navigate regional legal variations, consider intellectual property rights, and balance environmental benefits with safety standards for EECs and high-performance parts. Effective compliance requires understanding local emission standards, adhering to safety regulations, conducting rigorous testing, and maintaining meticulous documentation. Staying updated on evolving laws is crucial for successful implementation of EECs while mitigating potential risks and legal disputes.

“In an era driven by digital transformation, understanding the legal implications of electronic exhaust cutouts (EECs) is paramount. EECs, as innovative data privacy tools, offer both benefits and complexities in various industries. This article delves into the critical legal considerations surrounding EECs, exploring their impact on data protection, regulatory compliance, and best practices for implementation. By navigating the intricate landscape, businesses can harness the potential of EECs while mitigating associated risks.”

- Understanding Electronic Exhaust Cutouts and Their Legal Implications

- Key Legal Considerations for Implementation and Use

- Navigating Regulatory Landscape and Best Practices for Compliance

Understanding Electronic Exhaust Cutouts and Their Legal Implications

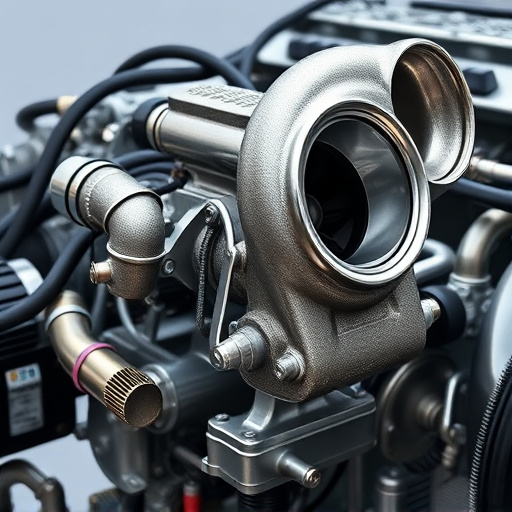

Electronic Exhaust Cutouts (EECs) are advanced emission control systems designed to reduce pollutants in vehicle exhaust gases. They work by electronically regulating and cutting off specific portions of the exhaust flow, thereby minimizing harmful emissions. Beyond their environmental benefits, EECs have significant legal implications, especially regarding vehicle regulations and safety standards.

The use of EECs is subject to strict laws and guidelines governing automotive emission controls. These regulations vary across regions but generally aim to curb air pollution and ensure vehicle safety. For instance, in many countries, EECs must be approved by relevant authorities to ensure they meet specific performance criteria for reducing nitrogen oxides (NOx) and particulate matter. Moreover, manufacturers must consider the compatibility of EECs with existing high-performance parts, such as coilover kits and advanced suspension components, while adhering to safety standards to prevent any potential risks or malfunctions.

Key Legal Considerations for Implementation and Use

When implementing electronic exhaust cutouts (EECs), several key legal considerations come into play to ensure compliance and safety. Regulations governing automotive technology vary across regions, so understanding local laws is paramount. EECs, which control or restrict engine exhaust, must adhere to emissions standards set by regulatory bodies. These standards are designed to limit harmful pollutants and ensure vehicles do not emit levels of gases that pose health risks.

Additionally, the integration of EECs into a vehicle’s system should consider intellectual property rights and any patents associated with the technology. Using or manufacturing brake components, including brake rotors, that incorporate EEC functionality may require licensing or permissions from the original equipment manufacturer (OEM) to avoid legal disputes. Similarly, for air intake systems that could be impacted by EECs, ensuring compliance with both environmental regulations and trademarked designs is crucial to protect against potential lawsuits.

Navigating Regulatory Landscape and Best Practices for Compliance

The regulatory landscape surrounding electronic exhaust cutouts (EECs) is a complex web that varies across jurisdictions. As these innovative suspension kits gain popularity, it’s crucial for manufacturers and users to navigate this terrain to ensure compliance. Key considerations include understanding local emission standards, which often dictate the type of EECs that can be used, as well as safety regulations related to exhaust tips and brake components. Staying informed about evolving laws is paramount.

Best practices for compliance involve rigorous testing and quality assurance for EECs to meet environmental and safety standards. This includes ensuring that exhaust systems, including any integrated electronic components, are designed and manufactured according to recognized industry guidelines. Proper documentation and record-keeping of all materials and processes used in the production of these suspension kits and associated parts, such as exhaust tips and brake components, are essential for transparency and accountability.

Electronic exhaust cutouts have evolved from a niche concern to a critical consideration in modern industries. As their usage expands, understanding the legal implications is vital for businesses to avoid regulatory pitfalls. By navigating the complex landscape of laws and best practices outlined in this article, organizations can ensure compliance and harness the benefits of electronic exhaust cutout technology while mitigating potential risks.