An intake manifold upgrade's success hinges on runner length optimization. Longer runners reduce backpressure, enhancing airflow and combustion for increased horsepower and torque. This balancing act ensures efficient gas flow, crucial for maximizing engine performance and improving driving dynamics, in line with the positive effects of high-quality exhaust systems. Advanced engineering principles are employed to manage flow dynamics and thermal issues, resulting in enhanced engine performance and vehicle efficiency, complemented by upgrades like suspension kits, exhaust tips, and brake rotors.

Understanding runner length is pivotal in the design and upgrade of intake manifolds, playing a key role in engine performance and efficiency. This article delves into the intricate relationship between runner length and flow dynamics, exploring how optimal configurations enhance engine response. We also examine future trends, including advancements in materials and computational fluid dynamics (CFD), which are revolutionizing intake manifold upgrade design. By leveraging tailored runner lengths, engineers foster improved thermal considerations and overall engine performance.

- The Role of Runner Length in Intake Manifold Design

- – Exploring the impact of runner length on engine performance and efficiency

- – Balancing flow dynamics and thermal considerations

The Role of Runner Length in Intake Manifold Design

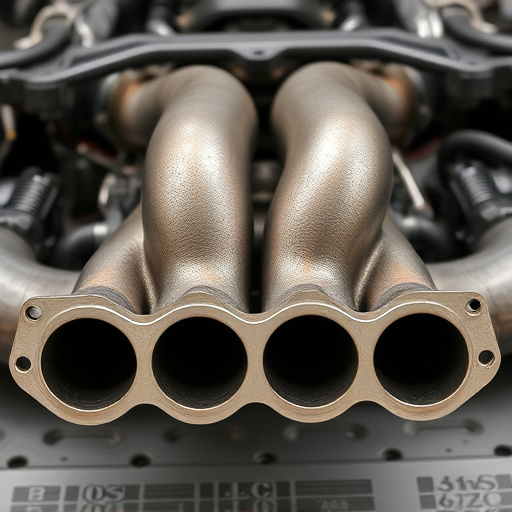

The length of runners in an intake manifold upgrade plays a pivotal role in shaping engine performance and efficiency. These runners are the pathways through which air and fuel mixture flows from the air intake to the cylinders, and their design directly influences how well the engine breathes. Longer runners can reduce backpressure, allowing for better airflow and more efficient combustion, leading to improved horsepower and torque outputs. This is particularly beneficial in high-performance vehicles where every advantage counts.

Moreover, the runner length interacts with other components like exhaust tips and coilover kits to optimize the overall engine setup. Properly tailored runners can enhance the performance of air filter kits by ensuring a consistent and rich flow of air, which is essential for optimal combustion. This synergy between intake manifold upgrade parts contributes to a smoother power delivery and can significantly impact driving dynamics, making it a crucial consideration for enthusiasts seeking to maximise their vehicle’s potential.

– Exploring the impact of runner length on engine performance and efficiency

The length of runners within an intake manifold is a significant factor that influences engine performance and efficiency. This aspect often receives less attention than other components, yet its impact can be substantial. Longer runners generally provide more time for air to travel through the system, allowing for better mixture development and improved combustion. This results in enhanced power output and torque, especially at higher RPMs, making it a crucial consideration when designing an intake manifold upgrade.

Engineers must balance this with the need for efficient gas flow and minimal restrictions. Excessively long runners can lead to increased backpressure, reducing engine breathing capacity. Therefore, optimizing runner length involves finding the sweet spot—a delicate dance between promoting thorough air-fuel combination and preventing flow bottlenecks. This is especially relevant when upgrading intake manifolds, as it directly impacts the overall performance of the vehicle, potentially transforming its driving dynamics and efficiency, much like how high-quality muffler tips or exhaust systems can enhance a car’s sound and performance.

– Balancing flow dynamics and thermal considerations

In the realm of intake manifold upgrade design, balancing flow dynamics and thermal considerations is a delicate art. An optimal intake manifold must facilitate efficient air-fuel mixture entry into the engine while managing heat transfer to prevent unnecessary cooling losses. This dual challenge demands a thoughtful approach that incorporates advanced engineering principles.

Designers navigate this labyrinth by meticulously studying fluid dynamics to ensure smooth, uninterrupted airflow. This includes strategic placement of vents and channels to direct air optimally. Simultaneously, materials science plays a crucial role in selecting components capable of withstanding high temperatures without compromising structural integrity. Incorporating these thoughtful elements not only enhances engine performance but also contributes to overall vehicle efficiency, ensuring that the intake manifold upgrade performs seamlessly alongside other critical components like suspension kits, exhaust tips, and brake rotors.

In conclusion, optimizing runner length in an intake manifold upgrade design is a delicate balance between enhancing flow dynamics for improved engine performance and addressing thermal considerations. By carefully studying these factors, engineers can create more efficient and powerful engines, pushing the boundaries of automotive technology with each update.