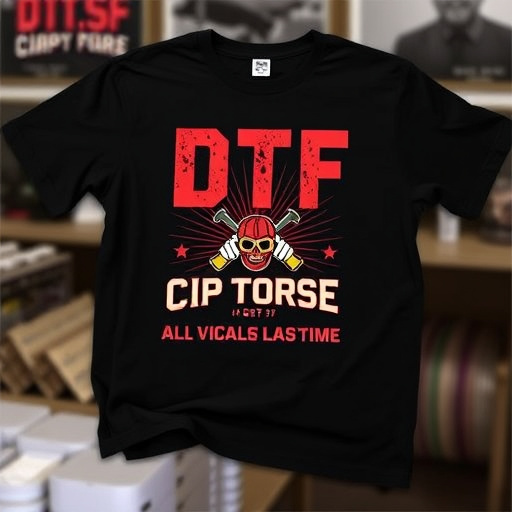

The DTF Powder Applicator revolutionizes direct-to-fabric (DTF) printing by offering precise, even powder distribution for consistent print quality on various fabrics, especially dark ones. Its ergonomic design, adjustable settings, and large application surface area enhance efficiency, reduce waste, and benefit bulk DTF shirt production. This innovative tool is a game-changer for clothing brands aiming to create high-impact designs using DTF heat transfer paper.

Discover the game-changing DTF Powder Applicator—a revolutionary tool transforming the way you handle powder-based products. In today’s market, precise and even distribution is key, ensuring customer satisfaction and product efficacy. This article explores the DTF Powder Applicator, its multifaceted benefits, and how it ensures optimal powder distribution. By understanding its role and key features, you’ll unlock enhanced application methods, setting a new standard in product presentation.

- Understanding the DTF Powder Applicator: Its Role and Benefits

- Key Features of an Effective DTF Powder Applicator

- Optimal Powder Distribution: How the DTF Applicator Transforms Product Application

Understanding the DTF Powder Applicator: Its Role and Benefits

The DTF Powder Applicator is a game-changer in the apparel industry, revolutionizing the way powder is applied during direct to fabric (DTF) printing processes. This innovative tool plays a pivotal role in ensuring optimal powder distribution, a critical step in achieving high-quality prints on various fabrics. By precisely controlling the powder application, it enhances the overall efficiency of DTF for apparel production, particularly when dealing with bulk DFT shirt production.

This applicator offers numerous benefits to printers and manufacturers. Firstly, it ensures consistent coverage, preventing powdery patches or missed spots that can occur with manual methods. This consistency is especially advantageous when printing on dark fabrics using DTF printing techniques, where the powder needs to adhere uniformly for optimal color transfer. The applicator’s ability to distribute powder evenly also reduces waste, as it minimizes the excess powder that often accumulates during traditional manual application methods.

Key Features of an Effective DTF Powder Applicator

A top-tier DTF Powder Applicator is an indispensable tool for achieving precise and even powder distribution, ensuring optimal results in direct-to-fabric (DTF) printing processes. Key features distinguishing effective applicators include ergonomic design for comfort during extended use, adjustable settings to cater to various powder types and fabric weights, and a large application surface area to minimize the time required for each print job.

Additionally, innovative applicators often incorporate elements like non-stick coatings to prevent powder buildup and easy cleanup, as well as built-in safety mechanisms to guard against accidental spills or overspray. These features are particularly beneficial for clothing brands leveraging DTF printing for light fabrics, where precise control over powder application is crucial for achieving vibrant logos and intricate designs on delicate materials. Moreover, the convenience of a cold peel DTF transfer process, which allows for swift removal of the powder after application, further underscores the importance of an efficient applicator in streamlining production workflows.

Optimal Powder Distribution: How the DTF Applicator Transforms Product Application

The DTF Powder Applicator is revolutionizing product application by ensuring optimal powder distribution, a key aspect often overlooked in traditional printing methods. This innovative tool is designed to transform the way businesses create and apply prints on various materials, especially in the realm of dtf heat transfer paper and logos DFT for clothing brands.

By utilizing advanced technology, the applicator evenly disperses powder across the surface, resulting in precise and consistent dtf prints. This meticulous process eliminates patches or uneven layers, ensuring every detail is crisp and clear. The optimal powder distribution achieved with this applicator enhances the overall quality of heat transfer designs, making it an indispensable asset for clothing brands aiming to create high-impact logos and graphics on their products.

The DTF Powder Applicator stands as a game-changer in product application, ensuring optimal powder distribution for enhanced efficiency and precision. By understanding its key features and benefits, businesses can revolutionize their packaging processes, leading to improved product quality and customer satisfaction. Incorporating this innovative tool is a strategic move towards staying ahead in the market, particularly with today’s demand for precise and effective cosmetic and pharmaceutical solutions.