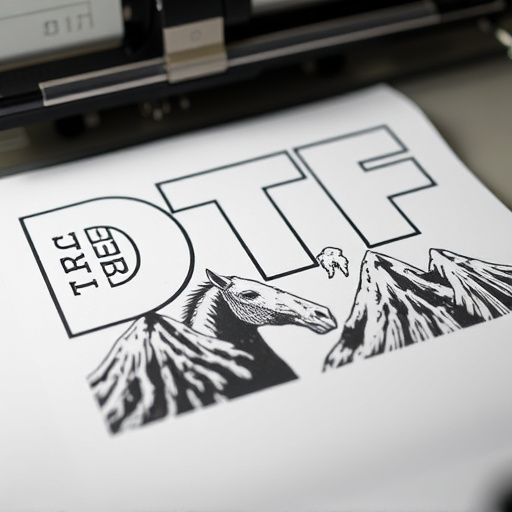

The evolution of T-shirt printing has transitioned from time-consuming screen printing to the efficient DTF (Direct to Garment) T-shirt printing. DTF uses heat pressing to apply custom ink sheets directly onto garments, enabling vibrant prints on various materials, even dark fabrics. This technology democratizes design, offering creators and businesses swift, cost-effective, and personalized T-shirt production—from small batches to individual orders. Compared to traditional screen printing, DTF printing provides faster turnaround times, eco-friendlier methods, broader fabric compatibility, and superior detail retention.

In the world of t-shirt printing, Direct-To-Fabric (DTF) technology is revolutionizing the industry. This innovative method offers a seamless evolution from traditional screen printing, addressing its limitations. DTF provides high-quality, vibrant prints on various fabrics and colors, with faster turnaround times and reduced environmental impact.

The article explores this game-changer, delving into its advantages and creative potential, including customization options for unique designs and the ability to print complex artwork, all while managing waste efficiently. Discover why DTF T-shirt printing is the future of the industry.

- The Evolution of T-Shirt Printing: From Traditional to DTF

- – A brief history of t-shirt printing methods

- – Limitations and drawbacks of traditional screen printing

The Evolution of T-Shirt Printing: From Traditional to DTF

The evolution of T-shirt printing has come a long way since its early beginnings. Traditional methods, like screen printing, have been around for decades, but they often involve time-consuming processes and limitations in terms of design complexity and color range. This led to the search for more efficient alternatives. Enter DTF (Direct to Garment) T-shirt printing.

DTF printing has revolutionized the way we adorn our apparel with art and designs. It offers a seamless, modern approach by applying custom sheets of ink directly onto garments using heat pressing. Unlike traditional methods that may struggle with dark fabrics, DTF transfer sheets excel in producing vibrant prints on various materials. This advancement has democratized T-shirt design, enabling creators and businesses to bring their unique visions to life swiftly and cost-effectively.

– A brief history of t-shirt printing methods

The history of T-shirt printing is a fascinating journey that has evolved significantly over time. From ancient techniques using wax and ink to block printing, the process has come a long way. The introduction of screen printing in the 20th century revolutionized custom apparel, allowing for more complex designs and vibrant colors. However, as technology advanced, new methods emerged, seeking to improve efficiency, quality, and versatility.

One such game-changer is Direct to Fabric (DTF) T-shirt printing, which has gained immense popularity in recent years. This modern technique uses a heat press machine to apply design on DTF transfer sheets directly onto the fabric. Unlike traditional methods like screen printing, which can be time-consuming and require bulk production setups, DTF offers a faster, more flexible approach. It enables the creation of unique, personalized T-shirts in small batches or even single pieces, making it an attractive option for businesses and individuals alike.

– Limitations and drawbacks of traditional screen printing

Traditional screen printing has long been the go-to method for custom t-shirt design, but it comes with several limitations and drawbacks. One of the main issues is the time-consuming nature of the process. Setting up a screen for each design requires creating individual masks, which can take hours or even days for complex artwork. This lengthy preparation phase slows down production time, making it less suitable for bulk orders or urgent requests.

Additionally, screen printing often involves using harmful chemicals and inks, which can be environmentally unfriendly. The process also limits the types of fabrics and designs you can create, as certain materials may not be compatible with the technique. This restriction hinders designers’ creativity and prevents them from experimenting with diverse fabric choices. Moreover, traditional methods struggle with intricate details and fine lines, resulting in potential smudging or bleeding of colors, especially when printing on dark garments.

DTF (Direct to Fabric) T Shirt Printing offers a revolutionary approach to customization, surpassing traditional screen printing methods in numerous ways. By eliminating the need for screens and reducing set-up times, DTF allows for faster production and more flexibility in design. This modern technique is ideal for small batch orders and one-off prints, ensuring high-quality results with vibrant colors and intricate details. With its advanced capabilities, DTF T Shirt Printing is transforming the industry, providing businesses and designers with an efficient and innovative way to bring their creative visions to life on apparel.