Regular cleaning and maintenance are crucial for keeping your DTF Transfers Printer in peak condition. This includes wiping down exterior surfaces, using specialized solutions to maintain the print head, proper storage of heat transfer paper, correct feeding, routine inspections, and deep cleaning to prevent clogs and damage. Combining these practices extends the printer's lifespan, ensures high-quality prints, and maintains optimal performance for custom garment printing.

Maintaining your DTF transfers printer effectively ensures optimal performance and consistent print quality. This guide delves into crucial aspects, starting with regular cleaning and maintenance routines to prevent buildup and ensure longevity. We explore best practices for ink and material management, emphasizing the selection of compatible components and efficient usage strategies. Additionally, we dissect calibration techniques and common troubleshooting issues, highlighting steps to resolve them promptly. Implement these tips to keep your DTF printer running smoothly.

- Regular Cleaning and Maintenance

- – The importance of routine cleaning

- – Steps for deep cleaning the printer

Regular Cleaning and Maintenance

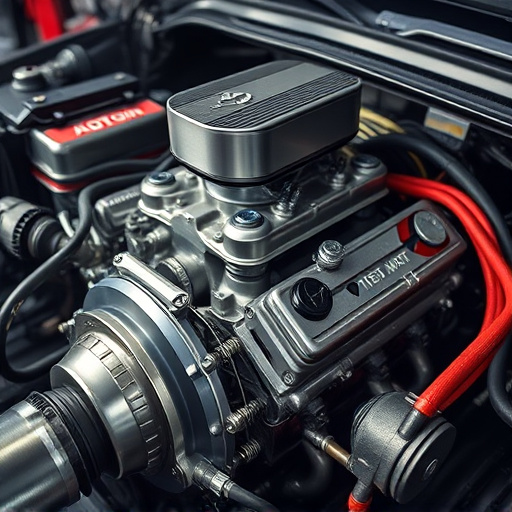

Regular cleaning and maintenance are essential to keep your DTF Transfers Printer in top condition. Start by wiping down the printer’s exterior with a damp cloth to remove any residual ink or debris. This simple step prevents build-up and ensures optimal performance. Additionally, it’s crucial to clean the print head regularly using specialized cleaning solutions designed for DTF printers. Clogged nozzles can lead to poor prints, so schedule periodic deep cleans according to the manufacturer’s recommendations.

Beyond surface cleanliness, maintain the quality of your DTF heat transfer paper. Store rolls in a cool, dry place away from direct sunlight and heat sources. Ensure the paper is fed into the printer correctly, aligning it precisely for sharp, accurate transfers. Regularly inspect the paper for any signs of damage or degradation, replacing it promptly if needed. By combining these cleaning practices with proper paper handling, you’ll maximize the lifespan of your DTF Transfers Printer and achieve consistently high-quality prints.

– The importance of routine cleaning

Regular cleaning is an essential part of maintaining your DTF Transfers Printer and ensuring optimal performance. Just like any other precision tool, a printer requires routine care to keep it in top condition. The build-up of residual ink, dust, or debris can significantly impact print quality, leading to inconsistent results on your custom sheets for heat pressing designs onto garments. A simple cleaning process involves using isopropyl alcohol and a microfiber cloth to wipe down the printing plate and rollers after each use. This prevents any dried ink from hardening and causing permanent damage.

Additionally, keeping your printer’s environment clean is vital. Regularly dusting the device and ensuring proper ventilation helps prevent blockages in the printing mechanism. It’s also advisable to clean the heat press itself, as residual heat transfer paper (DTF) can adhere and cause irregularities. With proper care and routine cleaning, you’ll extend the lifespan of your equipment and maintain consistent, high-quality prints for your garments.

– Steps for deep cleaning the printer

Deep cleaning your DTF Transfers printer is an essential part of maintaining its performance and extending its lifespan, especially when using it for custom dtf transfers and heat pressing designs onto garments. Start by power washing the exterior components to remove any accumulated dust or debris. Then, unplug the device and turn it upside down to allow any residual moisture to drain out completely. Next, disassemble the printer according to the manufacturer’s guidelines, taking special care with intricate parts. Use a soft brush or cloth to gently clean each component, paying close attention to nooks and crannies where dirt might hide. For more stubborn stains or buildup, use a mild cleaning solution suitable for printers.

After thoroughly drying all parts, reassemble the printer and ensure proper alignment. Consider using protective covers or storing the printer in a dust-free environment when not in use. Regular deep cleans will help maintain optimal printing quality and prevent clogs or damage to your DTF Transfers printer, ensuring consistent results with your custom sheets for heat pressing designs onto garments.

Regular maintenance is key to keeping your DTF Transfers printer in top condition. By following a simple cleaning routine and performing occasional deep cleans, you can ensure optimal performance and prolong the life of your printer. Remember, a well-maintained printer delivers higher-quality transfers and saves you time and money in the long run.