Rust, an electrochemical issue caused by moisture and oxygen exposure, damages metal structures over time, impacting vehicles' aesthetics and safety. Hydrophobic coatings, applied via professional PPF (Paint Protection Film) installation or vinyl wraps, create barriers against water and humidity, preventing rust formation and preserving vehicle protection and appeal for longer periods. These revolutionary protective layers enhance aesthetics and extend exterior life, making them valuable in industries exposed to varying environmental conditions like marine and automotive sectors.

Can hydrophobic coating be a game-changer in the battle against rust? This article explores how this innovative technology is revolutionizing material protection. We delve into understanding rust’s pervasive impact on various materials and its chemical intricacies. Subsequently, we uncover the science behind hydrophobic coatings, their ability to repel water and protect metal surfaces, and the numerous applications they offer. By adopting these advanced solutions, industries can enhance durability, reduce maintenance costs, and preserve structures and equipment in diverse environments.

- Understanding Rust and Its Impact on Materials

- The Role of Hydrophobic Coatings in Rust Prevention

- Applications and Benefits of Using Hydrophobic Coating to Combat Rust

Understanding Rust and Its Impact on Materials

Rust is a common issue that plagues many materials, particularly metals, leading to significant structural damage over time. It’s essentially an electrochemical process where metal oxidizes upon exposure to moisture and oxygen, resulting in the breakdown of its surface integrity. This not only compromises the material’s strength and durability but also opens up pathways for further corrosion, creating a cycle that can be detrimental to various applications, from industrial machinery to everyday transportation.

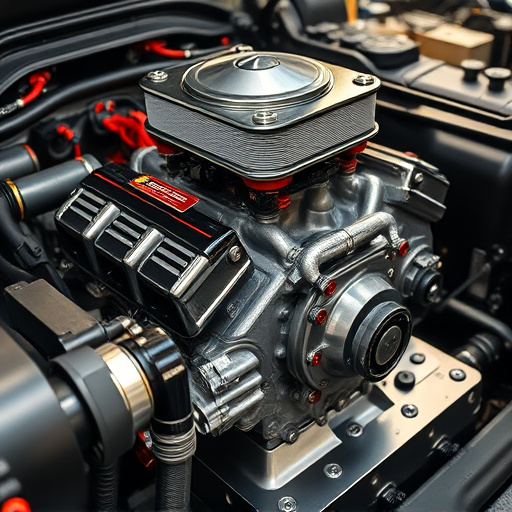

In the context of vehicles, rust can transform a sleek ride into an unsightly, fragile shell, reducing its value and safety. This is where hydrophobic coatings prove invaluable as a protective measure. These specialized coatings create a barrier between the metal surface and moisture, hindering the initial stages of corrosion. By repelling water and preventing moisture penetration, hydrophobic coatings, often applied via professional PPF installation or vinyl wraps, offer an effective solution for maintaining vehicle protection and preserving its aesthetic appeal for longer periods.

The Role of Hydrophobic Coatings in Rust Prevention

Hydrophobic coatings play a significant role in preventing rust formation by creating an effective barrier between metal surfaces and moisture. These innovative protective layers are designed to repel water and prevent it from penetrating the metal, which is the primary cause of rust. By blocking out humidity and other corrosive elements, hydrophobic coatings ensure that the metal remains dry and safe from oxidation.

This technology is particularly useful in industries where vehicles and machinery are exposed to various environmental conditions. For instance, custom graphics and window tinting services can incorporate hydrophobic coating during professional PPF (Paint Protection Film) installation, enhancing not only the aesthetics but also the longevity of vehicle surfaces. This dual benefit ensures that not only is the original finish protected, but the metal beneath is also safeguarded from rust, extending the life of the vehicle’s exterior.

Applications and Benefits of Using Hydrophobic Coating to Combat Rust

Hydrophobic coatings have found a wide range of applications in various industries due to their unique properties. When it comes to preventing rust formation, these coatings offer an effective solution. By creating a barrier between metal surfaces and moisture, they significantly reduce the risk of corrosion. This is especially beneficial in environments where water and humidity are prevalent, such as marine or automotive sectors.

One of the key advantages of hydrophobic coating is its ability to provide long-lasting protection with high-quality finishes. They can be applied to a variety of surfaces, including metallic car bodies, architectural structures, and even ceramic window tinting. Additionally, these coatings offer scratch protection, enhancing the durability and aesthetics of the coated items. This dual benefit makes them a preferred choice for those seeking both functional and decorative solutions to prevent rust damage.

Hydrophobic coatings emerge as a powerful tool in the fight against rust, offering a protective layer that repels water and moisture. By understanding the impact of rust on materials and leveraging the unique properties of hydrophobic coatings, various industries can extend the lifespan of metal structures and components. The applications are vast, from automotive to aerospace, with benefits including enhanced corrosion resistance, improved aesthetics, and cost savings. Adopting hydrophobic coating technologies is a strategic move towards more durable and reliable products in today’s demanding environments.