Backpressure management is key to maximizing performance in turbocharged vehicles. Turbo back exhaust systems, by routing exhaust gases efficiently, prevent pressure buildup behind turbines, enhancing engine output and fuel economy. This technology, combining larger pipes, optimized mufflers, and cold air intakes, improves turbine efficiency, increases throttle response, and extends brake life, making it a turbo back exhaust game-changer for high-performance vehicles.

Backpressure is a critical factor in turbo back exhaust design, influencing engine performance and efficiency. This article delves into the intricacies of understanding backpressure, focusing on its role in turbo exhaust systems. We explore how strategic design choices manage and optimize backpressure, enhancing overall engine output. By examining these aspects, we reveal the significant impact effective backpressure management has on both performance and fuel efficiency in modern vehicles equipped with turbo engines.

- What is Backpressure and Why Does it Matter in Turbo Exhaust Systems?

- How Turbo Back Exhaust Design Manages and Optimizes Backpressure

- The Impact of Effective Backpressure Management on Engine Performance and Efficiency

What is Backpressure and Why Does it Matter in Turbo Exhaust Systems?

Backpressure is a term often used in fluid dynamics to describe the resistance to flow within a system. In the context of turbo back exhaust designs, it refers to the pressure that builds up behind the turbine in a turbocharged engine. This occurs when the exhaust gases from the combustion chamber are expelled, creating a force that can impact the overall performance and efficiency of the vehicle.

Understanding backpressure is crucial for optimizing turbo exhaust systems, especially in high-performance vehicles with cold air intakes and powerful engines. In these setups, efficient gas flow through the exhaust system is essential to ensure the engine runs smoothly and maximizes power output. High performance parts, like turbos, rely on the correct balance of pressure differentials to function optimally, so managing backpressure is a key consideration in achieving peak performance with a turbo back exhaust.

How Turbo Back Exhaust Design Manages and Optimizes Backpressure

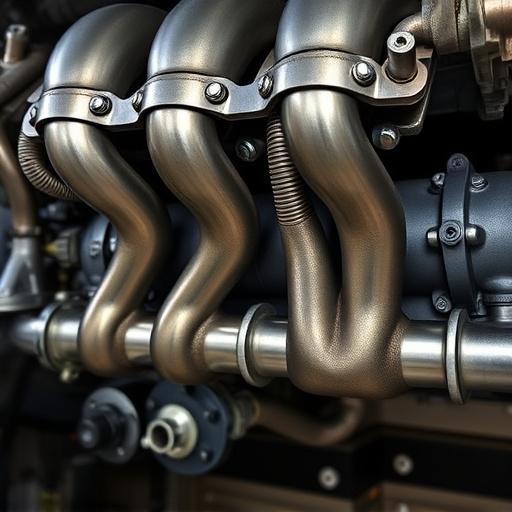

Turbo Back Exhaust Design manages and optimizes backpressure by intelligently routing exhaust gases away from the engine, allowing for more efficient combustion and improved performance. Unlike traditional cat back exhaust systems, which often restrict flow and create excess backpressure, turbo back designs incorporate specific components like larger diameter pipes, optimized mufflers, and strategically placed turbulators to enhance gas flow. This ensures that high-pressure exhaust gases are swiftly expelled, preventing buildup that can hinder engine output.

Additionally, integrating cold air intakes into the system further enhances performance by drawing in cooler, denser air, which is essential for efficient combustion. The seamless integration of these components creates a harmonious flow, reducing backpressure at the turbocharger and improving overall engine efficiency. This approach not only optimizes the turbo’s charging capabilities but also ensures that brake components are subjected to less stress due to reduced exhaust gas pressure, leading to longer lifespan and better overall vehicle performance.

The Impact of Effective Backpressure Management on Engine Performance and Efficiency

Effective backpressure management in a turbo back exhaust system plays a pivotal role in enhancing engine performance and efficiency. By meticulously controlling the flow of gases exiting the engine, manufacturers can optimize combustion, resulting in increased power output and improved fuel economy. This is particularly crucial in high-performance vehicles where every component contributes to achieving peak levels of acceleration and top speed.

Moreover, efficient backpressure regulation allows for better turbine efficiency within the turbocharger. With the right balance of pressure buildup and exhaust flow, the turbo can spin faster and maintain boost levels for longer durations. This translates into improved throttle response and a smoother power band, enhancing overall driver experience. Additionally, careful consideration of exhaust mufflers and muffler tips, coupled with performance air filters, contributes to achieving these goals while ensuring a quiet yet responsive driving experience.

Understanding backpressure is key to unlocking the full potential of turbo back exhaust systems. By managing and optimizing this force, engineers can significantly enhance engine performance and efficiency. Efficient backpressure management allows for smoother gas flow, improved turbine efficiency, and ultimately, better overall engine output, making turbo back exhaust designs a game-changer in the automotive industry.