DTF Durability goes beyond ink quality, encompassing a holistic approach to design longevity on t-shirts. It involves fabric adhesion, fading resistance, heat and laundry tolerance, and high-quality printing processes. Understanding the interplay of these elements—from transfer film to fabric compatibility—is key to appreciating the exceptional durability of DTF (Durable, Flexible, Waterproof) materials, suitable for apparel, signage, and more.

“Uncover the mysteries of DTF durability—a game-changer in modern material science. This article reveals seven surprising secrets that challenge common perceptions about what makes a product truly durable, flexible, and waterproof (DFT).

From myth-busting to exploring the scientific foundations and real-world applications, we delve into the key factors ensuring DTF materials stand the test of time. Discover how these innovations are revolutionizing industries, offering enhanced longevity and performance in diverse environments.”

- Unveiling the Myth: What Really Defines DTF Durability?

- – Debunking common misconceptions

- – Understanding the core factors contributing to DTF (Durable, Flexible, and Waterproof) materials' longevity

Unveiling the Myth: What Really Defines DTF Durability?

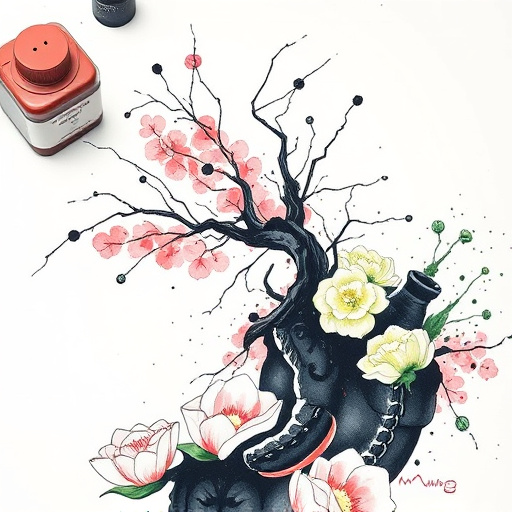

Many assume that DTF Durability is solely about the longevity of printed designs on t-shirts. However, delving deeper, we uncover a more nuanced definition. It’s not just about how long the ink lasts, but rather the overall durability of the entire printed component—from the adhesion of the DTF for t-shirts transfer film to the fabric, to the resistance of the design against fading and peeling over time. This comprehensive approach considers factors like heat exposure, laundry practices, and the quality of both the DTF printing for t-shirts process and materials used. Understanding these underlying elements allows us to truly grasp what constitutes exceptional DTF Durability.

– Debunking common misconceptions

Many believe that DTF (Direct to Fabric) durability is solely dependent on the quality of the print or the ink used. However, this is a common misconception. DTF durability involves a complex interplay between the fabric, the transfer sheet, and the printing process itself. The real secret lies in understanding how these elements work together. For instance, while high-quality inks can enhance longevity, it’s the precision of the print and the compatibility with the fabric that often make or break the final product.

Another myth is that DTF transfers are only suitable for smooth surfaces. In reality, advancements in technology have made DTF transfer sheets capable of adhering to a wide range of fabrics, even those with texture. This versatility opens up a world of possibilities for designers and manufacturers, allowing them to create durable prints on everything from t-shirts to flags. So, when it comes to DTF durability, don’t just focus on the ink; consider the entire process, from print precision to fabric compatibility, to achieve truly long-lasting results.

– Understanding the core factors contributing to DTF (Durable, Flexible, and Waterproof) materials' longevity

The durability of DTF (Durable, Flexible, and Waterproof) materials is a result of several key factors that contribute to their longevity. Firstly, the unique printing process behind DTF technology ensures superior adhesion, allowing for vibrant colours and intricate designs that withstand rigorous use and environmental conditions. This process involves transferring inks onto flexible substrates, creating a robust and durable finish.

Secondly, DTF-treated fabrics are designed to be resilient against wear and tear, making them suitable for various applications from apparel to signage. The flexible nature of the materials means they can conform to different shapes without compromising their structural integrity, while the waterproof properties further enhance their durability by protecting against moisture damage. Additionally, DTF transfer technology plays a vital role in ensuring that the colours and designs remain intact over time, even with frequent handling and exposure to sunlight.

Unveiling the true secrets of DTF durability reveals a complex interplay of material science and manufacturing precision. By understanding the core factors that contribute to its enduring reputation, we can appreciate the superior performance of DTF materials in various applications. Dispelling common myths allows us to recognize the genuine durability, flexibility, and waterproofing these materials offer. As we navigate a world increasingly demanding robust and long-lasting solutions, embracing the science behind DTF durability promises a brighter future for numerous industries.