Oiled air filters in high-performance vehicles improve engine intake airflow by lubricating synthetic mesh media, preventing buildup, and maintaining optimal fuel-air mixture. However, these modifications can disrupt Mass Airflow (MAF) sensors' sensitivity due to oil droplets and increased particulate matter, leading to compatibility issues and potential engine performance problems. For best results, users must select vehicle-compatible oil, follow replacement schedules, and choose the right air filter type to balance airflow and sensor health, ensuring optimal MAF functionality and overall vehicle efficiency.

Are oiled air filters a game-changer or a potential hazard for your vehicle’s mass airflow sensor (MAF)? This article delves into the intricate relationship between these components. Oiled air filters, while offering enhanced protection against dirt and debris, can impact MAF sensor performance due to their moisture retention. We explore the functionality of oiled air filters and their compatibility with MAF sensors, providing best practices to ensure optimal engine performance and accurate readings without compromising safety.

- Understanding Oiled Air Filters and Their Functionality

- The Role of Mass Airflow Sensors and Potential Compatibility Issues

- Best Practices for Using Oiled Air Filters with Mass Airflow Sensors

Understanding Oiled Air Filters and Their Functionality

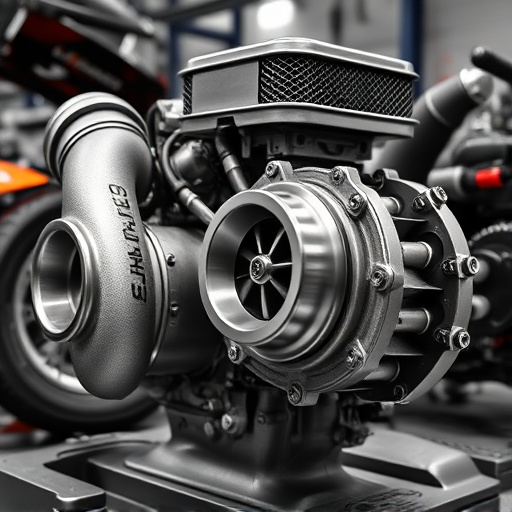

Oiled air filters are designed to capture and remove contaminants from the air entering a vehicle’s engine, particularly in vehicles with high-performance cold air intakes (CAIs) or modified exhaust systems. These filters use a fine mesh of synthetic materials coated with oil to trap particles like dust, pollen, and dirt. The oil not only enhances the filter’s efficiency but also acts as a lubricant, making it easier for air molecules to pass through while trapping smaller impurities. This is especially beneficial in environments with high levels of road debris or allergens.

By lubricating the filter media, oiled air filters can prevent excessive buildup on intake components, which could restrict airflow and potentially cause issues with mass airflow sensors (MAS). The MAS plays a crucial role in monitoring and regulating engine performance by measuring the volume of air entering the combustion chamber. Maintaining optimal airflow ensures the engine receives the correct fuel-air mixture, enhancing efficiency and reducing the risk of power loss or poor throttle response.

The Role of Mass Airflow Sensors and Potential Compatibility Issues

Mass Airflow Sensors (MAS) play a pivotal role in modern vehicle engine management systems, regulating and monitoring the flow of air into the engine for optimal performance and fuel efficiency. These sensors are integral to ensuring the engine receives the right mixture of air and fuel, which directly impacts power output and emissions control. However, when it comes to maintaining these delicate components, there’s a growing trend of using oiled air filters as an aftermarket modification, particularly with cold air intakes and air filter kits.

While oiled air filters are known for their ability to trap finer particles, they introduce oil droplets into the airflow, which could potentially disrupt the precise readings of the MAS. This is where compatibility issues arise; the sensor’s sensitivity makes it vulnerable to any foreign substances that might alter its accuracy. Furthermore, certain suspension kits designed for improved performance can also contribute to increased particulate matter in the air stream, exacerbating the potential risks to these sensors. As such, it’s crucial to consider the impact of such modifications on the overall health and functionality of the MAS to ensure the vehicle continues to perform at its best.

Best Practices for Using Oiled Air Filters with Mass Airflow Sensors

When using oiled air filters with mass airflow sensors (MAF), adhering to best practices is essential for optimal performance and sensor longevity. First, ensure that the oil used in the filter is compatible with your vehicle’s specifications; synthetic oils are often recommended as they don’t break down easily. Second, regularly check and replace the filter as per the manufacturer’s guidelines—neglecting this can lead to a buildup of contaminants that may damage the MAF sensor.

Additionally, consider the type of air filter you use. Performance air filters, while designed for enhanced airflow, might introduce excessive oil or debris into the engine bay, potentially affecting the sensor. Balancing performance brakes (in this context, improved filtration) with maintaining clean air flow is crucial. Regular maintenance and adherence to these practices will help keep your MAF sensor functioning correctly, ensuring optimal brake component performance and overall vehicle efficiency.

Oiled air filters can be a viable option for certain vehicle setups, but it’s crucial to understand their compatibility with mass airflow sensors. By following best practices and considering sensor sensitivity, drivers can ensure optimal performance and prevent potential issues. When used appropriately, oiled air filters can offer benefits in terms of flow efficiency and protection against contaminants, making them a safe choice for many applications. Always consult vehicle manuals and seek professional advice for specific needs.