A turbo wastegate is a crucial component in turbocharged engines, controlling boost pressure by diverting exhaust streams under specific pressure thresholds. This mechanism optimizes engine performance, prolongs turbocharger lifespan, and protects components from high-pressure wear. Modern wastegates use advanced actuation mechanisms for precise control, minimizing wear and enhancing turbo response times, leading to improved acceleration and power outputs. By accurately managing exhaust gas flow, turbo wastegate technology extends turbocharger lifespans, reduces maintenance needs, enhances fuel efficiency, and fosters a more sustainable driving experience.

“Unleash the power of efficient and lasting performance with the revolutionary turbo wastegate technology. This innovative component is transforming the turbocharger landscape, offering enhanced efficiency and extended lifespan. In this article, we delve into the fundamentals of turbo wastegates, exploring how they optimize engine performance while minimizing wear. From improved air flow to reduced heat buildup, discover why turbo wastegate technology is a game-changer for turbocharger dynamics.”

- Understanding Turbo Wastegates: The Basic Principles

- How Turbo Wastegates Improve Turbocharger Efficiency

- Benefits of Enhanced Longevity with Turbo Wastegate Technology

Understanding Turbo Wastegates: The Basic Principles

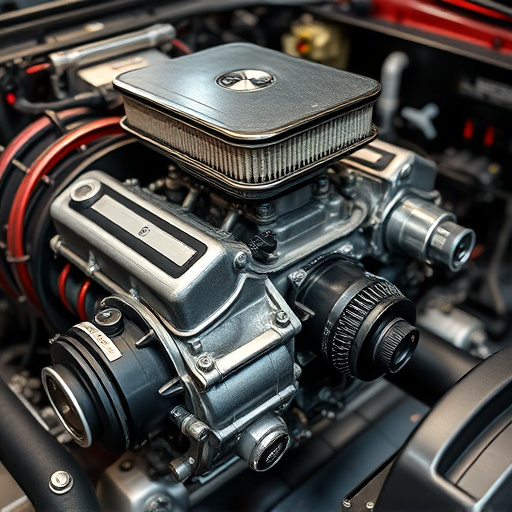

A turbo wastegate is a critical component in turbocharged engines, designed to regulate boost pressure by controlling the flow of exhaust gases around the turbine. It functions by diverting part of the exhaust stream away from the turbine during certain engine operating conditions, allowing for more efficient and effective turbocharger operation.

The basic principle behind a turbo wastegate involves utilizing a valve that opens and closes in response to changes in pressure within the exhaust system. When the exhaust gases passing through the turbocharger’s turbine reach a certain threshold pressure, the wastegate engages, redirecting some of the exhaust flow away from the turbine. This action reduces the turbine’s speed and subsequently lowers the boost pressure generated by the turbocharger. By managing boost pressure, the turbo wastegate optimizes both engine performance and turbocharger longevity, ensuring efficient air intake systems and protecting other components like exhaust mufflers and brake rotors from excessive wear caused by high-pressure conditions.

How Turbo Wastegates Improve Turbocharger Efficiency

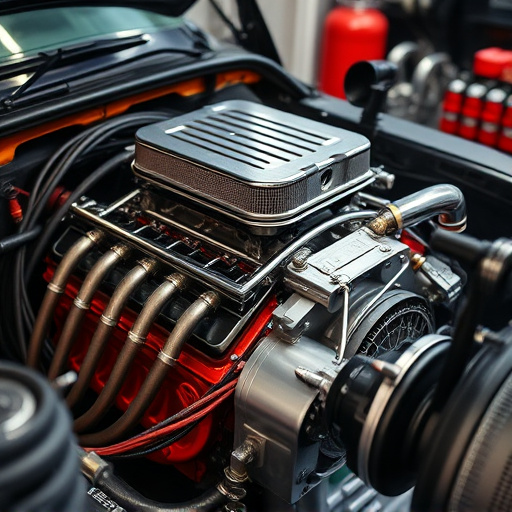

Turbo Wastegates play a pivotal role in enhancing turbocharger efficiency. By facilitating the rapid and controlled release of pressurized exhaust gases, they ensure that the turbine wheel spins efficiently, maximizing energy transfer from the exhaust to the compressor. This direct coupling results in improved turbo response times, enabling faster acceleration and higher power outputs. In essence, a turbo wastegate acts as a smart valve, optimizing the turbocharger’s performance across various engine speeds and loads.

Moreover, efficient wastegate operation contributes to longer turbocharger lifespan by reducing excessive stress on its components. Unlike traditional systems that rely solely on mechanical springs, modern wastegates incorporate advanced actuation mechanisms, often utilizing exhaust pressure itself or electric motors to control the valve. This precision control not only enhances efficiency but also minimizes wear and tear on critical turbo parts, such as bearings and seals, typically found in exhaust mufflers and exhaust systems. Even brake components benefit from this technology, as optimized wastegate operation reduces overheating and strain, ensuring better overall system health.

Benefits of Enhanced Longevity with Turbo Wastegate Technology

The adoption of turbo wastegate technology offers a significant advantage in extending the lifespan of turbochargers. This advanced system seamlessly integrates an additional valve to regulate exhaust gas flow, allowing for more precise control over turbine speed. By optimizing this process, the turbocharger operates at peak efficiency for longer periods, reducing wear and tear on its internal components.

This enhanced longevity translates into fewer maintenance requirements and lower replacement costs. Moreover, the improved performance brakes due to better air-fuel mixture control result in increased fuel efficiency and reduced emissions, contributing to a more sustainable driving experience. Additionally, high-quality turbo wastegate systems often come with air filter kits designed for optimal airflow, ensuring efficient engine performance throughout the vehicle’s life.

The integration of turbo wastegate technology represents a significant advancement in turbocharger design, offering both enhanced efficiency and longevity. By intelligently managing exhaust gas flow, turbo wastegates optimize turbine speed and minimize energy loss, leading to improved engine performance across various speeds. This innovation not only boosts the overall efficiency of turbocharged engines but also extends their lifespan by reducing wear and tear on critical components. As such, understanding and adopting turbo wastegate technology is a game-changer for automotive engineering, promising better fuel economy, increased power output, and reduced maintenance costs.