Charge pipes, essential components in high-performance vehicles, facilitate efficient fluid flow (e.g., engine oil, coolant, brake fluid) through lightweight, strong, corrosion-resistant materials like aluminum alloys or stainless steel. Their design considers temperature, pressure, and vibrations to prevent damage and maintain system reliability. Durability and flow efficiency depend on material selection, smooth internal surfaces, strategic diameter sizes & shapes, and integrated design considerations, enhancing overall vehicle performance. Advancements in materials science and manufacturing have revolutionized charge pipes through lightweight alloys, optimized geometry, advanced coatings, and sophisticated design software.

Charge pipes, essential components of modern vehicle cooling systems, play a pivotal role in managing heat dissipation. This article explores the intricate design and functionality of charge pipes, focusing on their critical roles in maximizing flow and ensuring durability. We delve into the factors influencing pipe longevity, from material choices to installation angles, offering insights for optimal performance. Additionally, we highlight advanced technologies pushing the boundaries of charge pipe efficiency. Understanding these aspects is key to harnessing the full potential of automotive cooling systems.

- Understanding Charge Pipes: Their Role and Basic Design Principles

- Factors Affecting Durability and Maximizing Flow in Charge Pipes

- Advanced Technologies and Innovations for Charge Pipe Efficiency

Understanding Charge Pipes: Their Role and Basic Design Principles

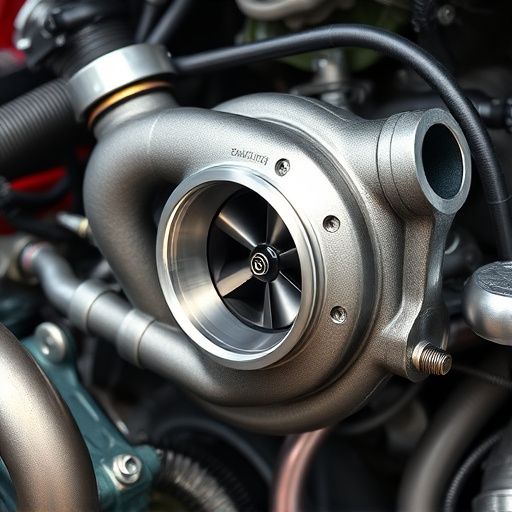

Charge pipes, a vital component in automotive systems, serve as the pathways for efficient fluid flow, particularly in vehicles with high-performance engines. Their primary role is to ensure the seamless movement of fluids, such as engine oil, coolant, or brake fluid, from the source to various components across the vehicle. These pipes are designed with careful consideration of material selection and structural integrity to withstand the extreme conditions they encounter.

Basic design principles for charge pipes emphasize light weight, strength, and corrosion resistance. Modern charge pipes often incorporate advanced materials like aluminum alloys or stainless steel to achieve these goals. They are meticulously engineered to balance flexibility and rigidity, ensuring optimal performance without compromising durability. This careful consideration extends to their connections with other systems, like suspension kits and exhaust tips, guaranteeing a secure fit that maintains fluid integrity. Additionally, the design accounts for temperature variations, pressure differentials, and potential vibrations to prevent failure or damage to brake components, ensuring the overall safety and reliability of the vehicle’s performance.

Factors Affecting Durability and Maximizing Flow in Charge Pipes

Several factors play a pivotal role in determining the durability and flow efficiency of charge pipes, essential components in high-performance vehicles. First and foremost is material selection; choosing the right pipe material can significantly enhance longevity. Stainless steel, for instance, offers excellent resistance to corrosion and heat, crucial for maintaining optimal performance over time. Additionally, the design of the charge pipes impacts their durability; smooth internal surfaces reduce friction and deposits, ensuring consistent airflow.

Furthermore, the size and shape of these pipes directly affect flow efficiency. Wider diameters can enhance airflow, especially when combined with strategically placed curves and bends. However, it’s a delicate balance; too much curvature might introduce restrictions, while minimal changes can optimize both durability and flow. Integrating these considerations ensures not just the longevity of charge pipes but also enhances the overall performance of related systems, such as air intake and even brake pads, by ensuring optimal fuel delivery in high-performance cars with advanced components like high-performance parts.

Advanced Technologies and Innovations for Charge Pipe Efficiency

In recent years, advancements in materials science and manufacturing techniques have significantly enhanced the efficiency of charge pipes. These innovations prioritize maximizing airflow while ensuring structural integrity, thereby boosting vehicle performance. Modern charge pipes are crafted from lightweight, high-strength alloys that resist corrosion and extreme temperatures, contributing to their longevity.

Moreover, technological leaps include sophisticated design software that optimizes pipe geometry for seamless air flow, much like how brake rotors are tailored for efficient cooling. Additionally, advanced coatings and finishes reduce friction and heat buildup, improving overall system performance, much akin to the sleek muffler tips designed for reduced noise and optimized exhaust flow.

Charge pipes, essential components in modern vehicle systems, have evolved significantly. By understanding their role, the factors impacting their durability and flow, and embracing advanced technologies, manufacturers can create efficient, long-lasting solutions. Optimizing these key areas ensures optimal performance and reduces maintenance costs, solidifying charge pipes as game-changers in the automotive industry.