Regular maintenance of blow off valves is vital for automotive performance and longevity. These valves release pressure from combustion chambers, reducing stress on engine components. Cleaning and inspecting for wear prevents clogs, ensures smooth operation, and prolongs the lifespan of high-performance parts. Proactive care, including cleaning, lubrication, and alignment checks, mitigates damage, enhances vehicle performance, and saves costs associated with engine repairs.

“Extend the lifespan of your machinery with proper blow off valve maintenance. These crucial components play a vital role in venting compressed air, preventing damage from pressure buildup. This article guides you through the essentials, including understanding blow off valves, their basic care, and regular cleaning routines. Learn to identify common issues and employ long-term strategies for optimal performance. Discover why maintaining these vents is essential for efficient, reliable operations.”

- Understanding Blow Off Valves: Their Role and Basic Maintenance

- Regular Cleaning and Inspection: Keeping Your Blow Off Valves in Top Shape

- Common Issues and Long-Term Care Strategies for Optimal Performance

Understanding Blow Off Valves: Their Role and Basic Maintenance

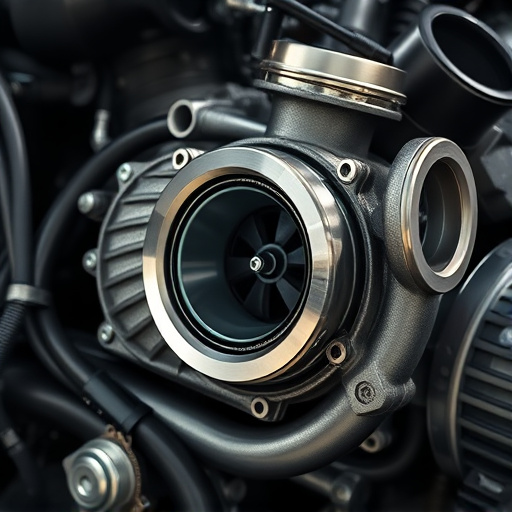

Blow off valves are essential components in automotive engineering, specifically designed to release pressure from the engine’s combustion chamber. They play a crucial role in maintaining optimal performance and longevity of internal combustion engines. By allowing for the controlled expulsion of gases, these valves prevent backpressure from building up within the system. This not only enhances engine efficiency but also reduces stress on various parts, including critical components like brake pads and exhaust tips.

Regular maintenance is vital to ensure blow off valves function efficiently over an extended period. A simple yet effective strategy involves keeping them clean and free from debris. As air intake systems are a common point of contamination, periodic cleaning can significantly improve valve performance. Additionally, checking for wear and tear, especially on the seals, should be part of any maintenance routine. Early detection of issues ensures timely replacement, preventing potential damage to other engine parts, thereby saving costs and prolonging the life of your vehicle’s power train.

Regular Cleaning and Inspection: Keeping Your Blow Off Valves in Top Shape

Regular cleaning and inspection are vital components in maintaining your blow off valves for longevity. Dust, debris, and carbon buildup can clog these essential components, leading to reduced performance and potential damage. A simple yet effective cleaning routine involves disassembling the valve and using compressed air to blast away any obstructions. This process not only ensures smooth operation but also prolongs the lifespan of your high-performance parts, such as brake rotors and suspension kits.

During inspection, look for signs of wear, corrosion, or damage. Regular visual checks can help you catch issues early on, preventing more serious problems down the line. It’s a good practice to compare the condition of your blow off valves with new ones, noting any deviations that might require replacement parts. This proactive approach will keep your vehicle running optimally and ensure top-notch performance when combined with other maintenance tasks, like keeping your suspension kits in peak condition.

Common Issues and Long-Term Care Strategies for Optimal Performance

Blow off valves, integral components in many vehicles, particularly those with modified engines and cold air intakes, serve to regulate pressure in the engine’s combustion chamber. Over time, they can face common issues such as debris buildup, corrosion, or misalignment, leading to reduced performance and potential damage to other engine parts. Long-term care strategies include regular cleaning and lubrication, ensuring proper alignment, and monitoring for unusual noises or performance indicators.

Regular maintenance with high-quality fluids and coilover kits designed for optimal valve function can significantly extend the lifespan of these components. By keeping blow off valves in peak condition, vehicle owners not only enhance overall vehicle performance but also prevent costly repairs down the line. This proactive approach ensures that modifications like cold air intakes continue to provide benefits without compromising engine health.

Proper maintenance of blow off valves is key to ensuring their longevity and optimal performance. By regularly cleaning and inspecting these vital components, you can prevent common issues and keep your vehicle running smoothly. Remember to address any concerns promptly to avoid costly repairs down the line. With the right care, your blow off valves will continue to enhance your driving experience for years to come.