Unusual noises and vibration patterns during acceleration, deceleration, or idling—like squealing, clicking, knocking, rattling, or high-pitched whining—can signal internal damage to engine components. Regular monitoring through noise checks, visual inspections, tracking key performance metrics (temperature, oil pressure, exhaust gas temps, fuel efficiency), and setting automated alerts for anomalies enables proactive maintenance and prevents costly repairs. Conducting visual inspections for corrosion, cracks or unusual wear patterns, maintaining air filters and exhaust systems, and checking for fluid accumulation are critical. Advanced diagnostic tools assist in early detection of internal damage by pinpointing leak sources.

Unsure if your engine is hiding internal damage? Recognizing subtle signs can prevent costly breakdowns. This comprehensive guide equips you with the knowledge to identify potential issues in critical engine components. From unusual noises and vibration patterns, to monitoring performance metrics and performing visual inspections for leaks, learn the red flags that could indicate hidden problems. By staying vigilant, you can ensure optimal engine health and extend the life of your vehicle’s vital powerplant.

- Identifying Unusual Noises and Vibration Patterns

- Monitoring Engine Performance Metrics

- Visual Inspection and Leakage Detection

Identifying Unusual Noises and Vibration Patterns

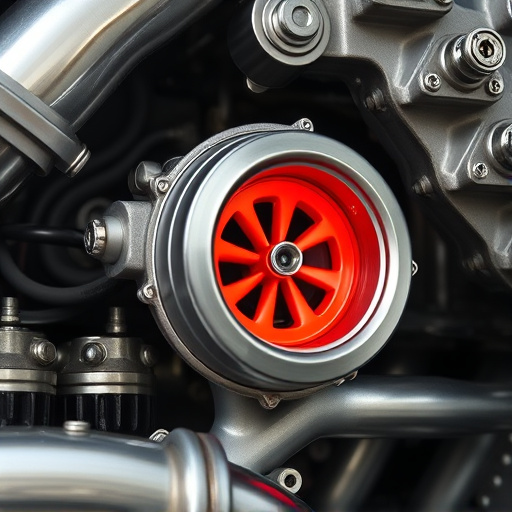

Unusual noises and vibration patterns can be early indicators of internal damage to engine components. Pay close attention to any new or persistent sounds coming from your vehicle, especially during acceleration, deceleration, or idling. Squealing, clicking, knocking, rattling, or a high-pitched whining could suggest issues with bearings, pistons, valves, or the timing belt. Even muffler tips and exhaust mufflers can exhibit telltale signs of wear, such as a loud rumble or droning noise, indicating potential problems with the exhaust system.

Regularly checking your vehicle’s noise levels and vibration patterns allows for proactive maintenance. If you notice any anomalies, don’t ignore them—they could save you from more serious and costly repairs down the road. Keep an ear out for these warning signs, along with checking your air filter kits and exhaust components, to ensure optimal engine health.

Monitoring Engine Performance Metrics

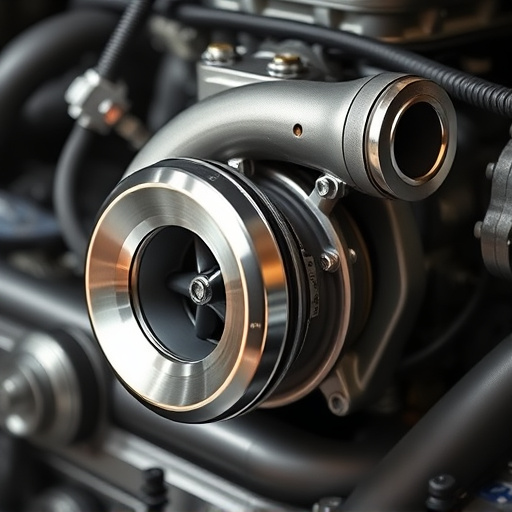

Regularly monitoring engine performance metrics is a crucial step in identifying potential internal damage to hidden components early on. This includes tracking key indicators such as temperature, oil pressure, and exhaust gas temperatures. By setting up automated alerts for anomalies, vehicle owners can promptly address issues before they escalate. For instance, unusual spikes in temperature could signal problems with cooling systems or worn-out engine bearings.

Additionally, keeping an eye on fuel efficiency and power output variations can provide insights into the overall health of engine components. Discrepancies in these metrics may hint at worn high performance parts, like exhaust tips or brake pads, which require timely replacement to maintain optimal engine performance and prevent further damage to sensitive engine parts.

Visual Inspection and Leakage Detection

A thorough visual inspection is often the first step in identifying potential internal damage to engine components. Look for any signs of corrosion, cracks, or unusual wear patterns on critical parts like pistons, valves, and cylinder heads. Even small indications of distress can suggest underlying issues that may lead to more severe problems if left unaddressed. Regular maintenance, including timely replacement of essential items such as air filter kits, intake components, and performance exhaust systems, can help prevent visual damage from buildup or wear over time.

Leakage detection is another critical aspect. Check for any unusual fluid accumulation around the engine bay, which could point to leaks in seals, gaskets, or hoses. These issues often manifest as subtle drips or puddles and might go unnoticed without close inspection. Advanced diagnostic tools can also aid in pinpointing the exact location and cause of leaks, ensuring that internal damage is identified early on.

In detecting internal damage to hidden engine components, a multi-faceted approach is key. By combining unusual noise and vibration patterns with close monitoring of performance metrics and meticulous visual inspections for leaks, vehicle owners can effectively identify potential issues early on. Regular maintenance, coupled with these strategies, plays a pivotal role in ensuring the longevity and optimal performance of crucial engine components.