DTF Quick Turnaround Printing is a game-changer in the apparel industry, offering a rapid and efficient custom garment production process. By directly applying heat-transfer designs to fabrics using advanced Direct to Fabric (DTF) technology, this method cuts out traditional printing steps and significantly reduces turnaround time—from hours to minutes. This speed allows businesses to swiftly adapt to market trends, manage demand, and enhance customer satisfaction, ensuring a strong competitive edge in the dynamic business landscape. To maximize DTF Quick Turnaround's benefits, invest in modern equipment, streamline design processes, and maintain efficient inventory management.

In today’s fast-paced business environment, quick turnaround times are crucial for success. DTF (Direct To Final) quick turnaround printing stands out as a game-changer, offering unparalleled efficiency and speed. This article explores why speed matters in DTF Quick Turnaround Printing, delving into the benefits of meeting tight deadlines and exceeding customer expectations. We’ll uncover strategies to optimize the process, ensuring your business stays competitive and delivers outstanding results promptly.

- Understanding DTF Quick Turnaround Printing: Unlocking Efficiency

- The Impact of Speed: Meeting Tight Deadlines and Customer Expectations

- Strategies to Optimize Speed: Enhancing the DTF Quick Turnaround Process

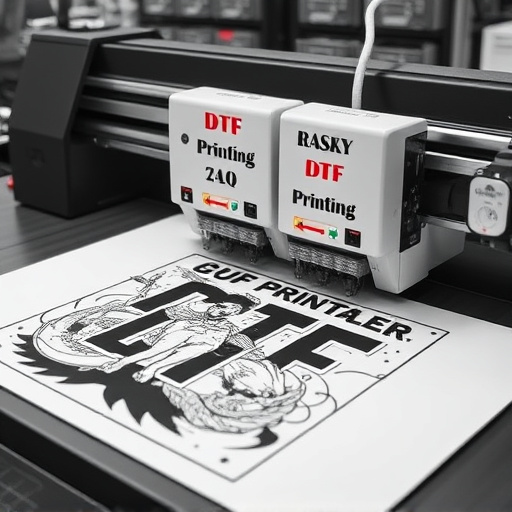

Understanding DTF Quick Turnaround Printing: Unlocking Efficiency

DTF Quick Turnaround Printing is a game-changer in the apparel industry, revolutionizing how businesses handle custom garment production. This innovative process, also known as Direct to Fabric (DTF), allows for an unprecedented level of efficiency. By eliminating the need for traditional printing methods and intermediate materials, DTF for t-shirts and other garments offers a streamlined approach. It directly applies heat-transfer designs onto custom sheets, which are then pressed onto fabrics, making it ideal for light fabrics that may not be suitable for standard printing techniques.

This technology’s true power lies in its quick turnaround time. Custom sheets for heat pressing designs can be printed and ready for application within hours, significantly reducing production delays. This rapid response is a significant advantage for businesses catering to fast-paced trends or urgent customer requests. DTF printing’s ability to unlock efficiency without compromising quality ensures it remains a preferred choice for those seeking to stay ahead in the competitive apparel market.

The Impact of Speed: Meeting Tight Deadlines and Customer Expectations

In the fast-paced world of modern business, speed is a critical factor that can make or break an organization’s success, especially in printing industries. DTF (Direct to Fabric) quick turnaround printing offers a unique advantage by enabling businesses to meet tight deadlines and customer demands efficiently. The impact of printing speed is profound when it comes to time-sensitive projects and limited-edition releases. With DTF technology, companies can produce high-quality, customized designs on various items like hoodies or shirts in a matter of hours, ensuring a swift response to market trends and consumer preferences.

This rapid turnaround is particularly valuable for bulk production runs, where efficiency is key. Businesses can quickly adapt to fluctuating demand, offering customers the latest designs without incurring excessive costs or delays. Moreover, DTF printing’s speed contributes to enhanced customer satisfaction, as orders are fulfilled promptly, allowing brands to build a reputation for reliability and responsiveness in a highly competitive market.

Strategies to Optimize Speed: Enhancing the DTF Quick Turnaround Process

To optimize speed and enhance the DTF (Direct to Garment) Quick Turnaround process, several strategies can be implemented. Firstly, investing in state-of-the-art printing equipment designed for rapid production can significantly reduce turnaround time. These machines are often equipped with advanced features like automatic feeding mechanisms and high-resolution printers, ensuring a smoother workflow.

Additionally, streamlining the design process is key. Using user-friendly software that allows for easy vectorization of graphics and simplifies complex designs can save valuable time. Custom sheets for heat pressing designs onto garments should be prepared in advance, minimizing delays during the actual printing phase. Efficient inventory management and pre-planning for frequently requested colors and materials also contribute to a faster turnaround, ensuring clients receive their orders promptly.

In conclusion, the speed at which DTF quick turnaround printing operates is a defining factor in its success. By understanding the technology and implementing strategic optimizations, businesses can meet tight deadlines and exceed customer expectations. The ability to deliver high-quality prints promptly not only enhances operational efficiency but also solidifies relationships with clients who rely on swift production times. This agile approach positions DTF quick turnaround printing as a game-changer in today’s fast-paced business landscape.