Assessing and disassembling an engine after damage involves inspecting key components like cylinder heads, pistons, valves, exhaust systems, and brake pads to determine repair needs. Core engine components, such as cylinder heads, pistons, and crankshafts, should be replaced if worn or damaged. Reassembly requires meticulous alignment and fit, with testing to ensure optimal performance. Upgrading parts can enhance output and handling, resulting in a reliable engine ready for any road condition.

Rebuilding your engine after major damage can seem daunting, but with a systematic approach, it’s achievable. This comprehensive guide walks you through the process of assessing and disassembling a damaged engine, repairing or replacing critical engine components, and finally reassembling, testing, and optimizing performance. From understanding the extent of the damage to fine-tuning for peak efficiency, learn how to bring your engine back to life with expert advice on engine components restoration.

- Assessing Engine Damage and Disassembly Procedure

- Repairing and Replacing Key Engine Components

- Reassembly, Testing, and Performance Optimization

Assessing Engine Damage and Disassembly Procedure

Assessing Engine Damage and Disassembly Procedure

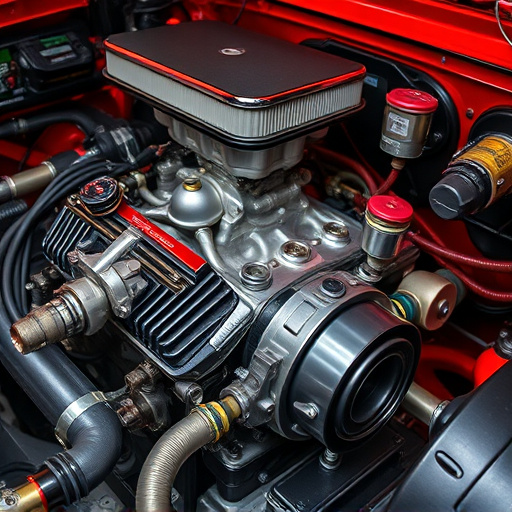

The first step in rebuilding engine components after major damage is a thorough assessment. This involves visualizing and diagnosing the extent of the harm, taking into account various parts like cylinder heads, pistons, valves, and more. Inspecting critical components such as brake pads, which can signal issues with stopping mechanisms, and examining exhaust systems including cat back exhaust and exhaust mufflers, helps in understanding the root cause of the damage. This process is crucial for effective disassembly, ensuring that every damaged part is identified and addressed accurately.

Disassembly then becomes a meticulous procedure where each engine component is carefully taken apart to access internal areas. This involves removing bolts, unbolting connections, and using specialized tools to separate parts. The goal is to gain full visibility of the damaged areas while preserving as much intact material as possible for rebuilding or replacement. By following this methodical approach, technicians can accurately assess the feasibility of repairing specific engine components, ensuring a successful rebuild.

Repairing and Replacing Key Engine Components

When rebuilding an engine after major damage, repairing and replacing key components is a critical step. These include vital parts like the cylinder head, pistons, and crankshaft. Inspection should be thorough, looking for signs of wear, cracks, or deformations that could indicate further damage or weakness. For instance, exhaust mufflers, which are integral to an engine’s performance and noise reduction, must be checked for any leaks or structural integrity issues.

Coilover kits, often used to enhance suspension systems, can also be part of the replacement process if they are found to be compromised. Similarly, ensuring that exhaust systems are in good condition is essential, as these components play a significant role in engine performance and emissions control. Proper assessment and replacement of these key engine components lay the groundwork for reliable and efficient operation once the rebuilding process is complete.

Reassembly, Testing, and Performance Optimization

After carefully repairing or replacing damaged engine components, the next crucial step is reassembly. This involves meticulously putting all the pieces back together, ensuring proper alignment and fit. A systematic approach is essential here; each component must be installed correctly to maintain optimal performance. Once the engine is thoroughly assembled, rigorous testing becomes paramount. Running various diagnostic checks helps identify any potential issues early on. This phase also includes evaluating the overall functionality and efficiency of the engine.

To ensure peak performance, consider upgrading certain parts like high-flow performance air filters, coilover kits for precise suspension control, or even replacing worn-out brake rotors for better stopping power. These modifications can significantly enhance the overall output and handling of the vehicle. Through a combination of thorough testing and strategic upgrades, you’ll have a reliable engine with improved performance ready to tackle any road ahead.

Rebuilding engine components after major damage is a complex process that requires careful assessment, meticulous disassembly, and precise repair techniques. By following the steps outlined in this article—from assessing damage and disassembling the engine to repairing key components and optimizing performance through reassembly—you can effectively revive a damaged engine, ensuring its reliability and efficiency. Remember, proper maintenance and timely repairs are essential for extending the lifespan of your engine components.