Electronic Exhaust Cutout (EEC) systems enhance vehicle performance and reduce noise pollution by controlling exhaust gas flow. Proper installation, regular inspections, component replacements, secure connections, and adherence to manufacturer guidelines are vital to prevent leaks. Proactive maintenance, including fluid level checks, seal replacement, and debris removal, ensures optimal EEC operation, prevents costly breakdowns, and boosts overall vehicle performance.

In the realm of automotive engineering, electronic exhaust cutout (EEC) systems have revolutionized noise control. However, these sophisticated mechanisms are not immune to leaks, which can compromise performance and efficiency. This article guides you through a comprehensive approach to prevent EEC leaks. We explore common issues, from sensor malfunctions to sealing problems, offering practical steps for real-world applications. Additionally, we delve into maintenance strategies designed to ensure longevity and optimal functionality of your electronic exhaust cutout systems.

- Understanding Electronic Exhaust Cutout Systems and Common Leakage Issues

- Practical Steps to Prevent Leaks in Real-World Applications

- Maintenance Strategies for Longevity and Efficiency

Understanding Electronic Exhaust Cutout Systems and Common Leakage Issues

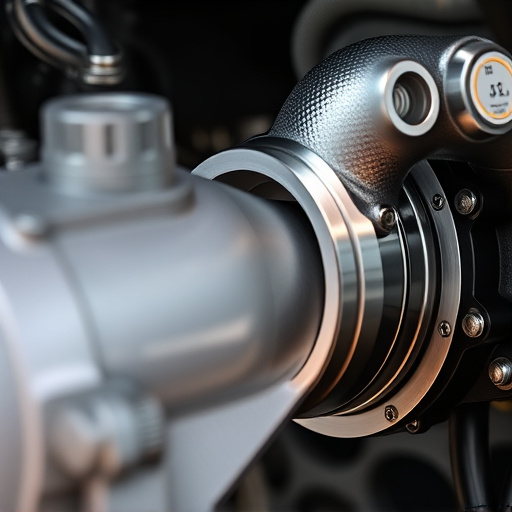

Electronic Exhaust Cutout Systems (ECOS) are advanced control mechanisms designed to manage and optimize vehicle performance by electronically adjusting exhaust gas flow. These systems play a crucial role in enhancing engine efficiency, reducing noise pollution, and improving overall driving experience. ECOS work in conjunction with various components like sensors, actuators, and controllers to regulate the opening and closing of exhaust valves or vents. While they offer numerous benefits, proper maintenance is essential to prevent common leakage issues that can compromise performance and efficiency.

Leakages in ECOS often occur due to faulty installation, worn-out seals, or damage to the system’s intricate parts. One frequent issue involves muffler tips, where cracks or disconnections can lead to significant exhaust gas escape. Similarly, air intake systems connected to the ECOS may develop leaks at joints or gaskets, allowing unburned fuel and air to mix, affecting engine performance. Effective prevention strategies include regular inspection and replacement of worn components, ensuring secure connections, and adhering to manufacturer guidelines for maintenance and repair.

Practical Steps to Prevent Leaks in Real-World Applications

To prevent leaks in real-world applications of electronic exhaust cutout (EEC) systems, start by ensuring proper installation. Use high-quality gaskets and seals designed for automotive use, and double-check connections to avoid any gaps or misalignments. Regularly inspect these components for signs of wear or damage, replacing them as needed. Additionally, consider the compatibility of your EEC system with existing air intake systems and brake rotors, as improper integration can lead to leaks.

Implementing proactive maintenance is crucial. This includes regular cleaning of the EEC unit and its surrounding components, especially when dealing with cold air intakes, which can accumulate dust and debris over time. Lastly, monitor the overall condition of your vehicle’s engine bay. Keep it organized and free from clutter that could obstruct access to critical components, making inspection and maintenance easier and reducing the risk of accidental damage that might cause leaks.

Maintenance Strategies for Longevity and Efficiency

Regular maintenance is key to ensuring your electronic exhaust cutout (EEC) systems operate efficiently and leak-free over time. A well-maintained EEC can significantly improve vehicle performance and extend its lifespan. Start by inspecting all fluid levels, especially those in the brake components and intake system, as these are common areas for leaks. Top up or replace fluids as needed, ensuring you use only high-quality products recommended by the manufacturer.

Next, focus on tightening connections and replacing any worn-out seals or gaskets within the EEC. Even a minor gap can lead to performance issues and leaks. Remember, proper maintenance isn’t just about fixing problems; it’s also preventive care. By keeping your EEC in top condition, you reduce the risk of unexpected breakdowns and costly repairs, ensuring your vehicle’s engine remains at peak performance.

Preventing leaks in electronic exhaust cutout (EEC) systems is crucial for maintaining efficiency and longevity. By understanding common issues like sensor misalignment, wiring damage, and seal wear, you can take proactive steps to enhance system integrity. Regular maintenance, including periodic inspections, prompt repairs, and replacing worn components, ensures optimal performance. Adhering to best practices in installation and monitoring can significantly reduce the occurrence of leaks, ultimately enhancing the overall reliability of EEC systems.