DTF Transfer Gang Sheets are game-changers for print turnaround, utilizing Direct to Fabric (DTF) technology to enable fast, precise printing on fabric and smooth surfaces. With multi-print areas and various sizes, these sheets streamline batch processing for custom apparel and home decor production, minimizing wait times, overhead costs, and waste while ensuring vibrant design replication and consistent quality across every piece. Implementing DTF Transfer Gang Sheets significantly speeds up Direct-To-Garment (DTF) printing processes, optimizing production efficiency and customer satisfaction.

“Revolutionize your print turnaround times with DTF Transfer Gang Sheets! This innovative technology is transforming the printing industry, offering unparalleled speed and efficiency. In this comprehensive guide, we’ll explore what DTF Transfer Gang Sheets are, how they work, and why they’re a game-changer for businesses. From understanding the basic concept to implementing this method, you’ll discover the benefits of faster print production without compromising quality. Get ready to dive into the future of printing.”

- Understanding DTF Transfer Gang Sheets: An Overview

- Benefits of Using DTF Transfer for Rapid Print Turnaround

- Implementing DTF Transfer Gang Sheets: A Step-by-Step Guide

Understanding DTF Transfer Gang Sheets: An Overview

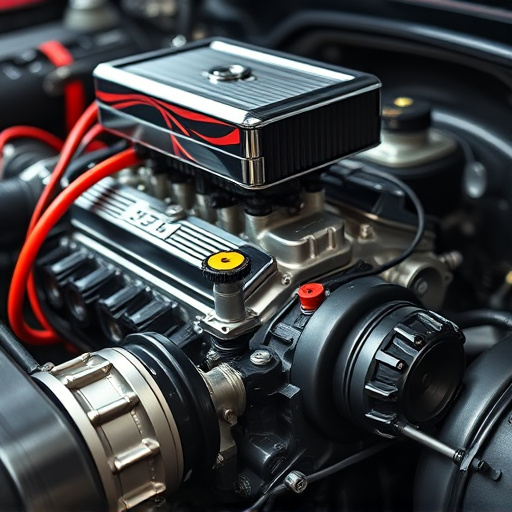

DTF Transfer Gang Sheets are a game-changer when it comes to fast print turnaround times. These specialized sheets allow for efficient transfer of vibrant designs onto various materials, making them ideal for businesses and individuals seeking quick customization options. By utilizing DTF (Direct to Fabric) technology, these sheets enable precise printing directly onto fabric or other smooth surfaces without the need for traditional screen printing methods.

Each gang sheet is designed with multiple print areas, allowing for batch processing of orders. This means that designers and printers can easily produce a range of custom products quickly, from apparel to home decor items. Moreover, DTF Transfer Gang Sheets come in various sizes, catering to different project requirements. Whether it’s creating personalized t-shirts, reusable masks, or even small accessories, these sheets offer versatility and high-quality results, ensuring that vibrant designs are accurately replicated on every piece produced.

Benefits of Using DTF Transfer for Rapid Print Turnaround

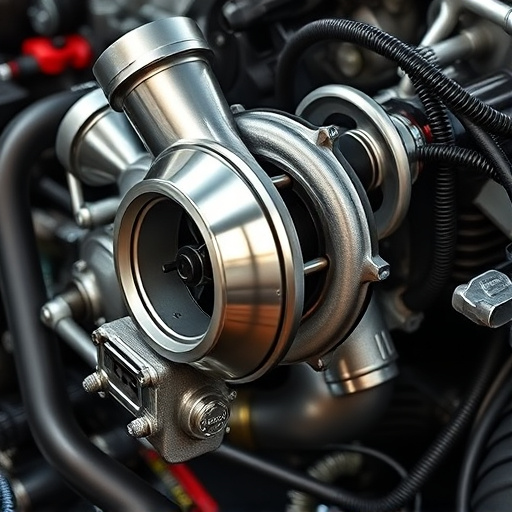

Using DTF (Direct to Fabric) Transfer Gang Sheets for print turnaround offers a multitude of benefits, especially in fast-paced industries where speed and efficiency are paramount. The process allows for precise and vibrant designs to be swiftly transferred onto various fabrics, enabling businesses to meet tight deadlines with consistent quality. This is particularly advantageous for bulk orders, as DTF technology streamlines the production line, minimizing wait times and maximizing productivity.

DTF design transfers present a cost-effective solution, eliminating the need for intricate set-up processes often associated with traditional printing methods. This efficiency not only accelerates turnaround times but also reduces overhead costs. Furthermore, DTF bulk orders allow businesses to cater to diverse customer demands, ensuring that orders of any size can be handled swiftly and effectively, without compromising on design integrity or print quality.

Implementing DTF Transfer Gang Sheets: A Step-by-Step Guide

Implementing DTF Transfer Gang Sheets is a streamlined process designed to accelerate print turnaround times significantly. These specialized sheets, optimized for Direct-To-Garment (DTF) printing, allow for efficient organization and management of design layouts across multiple garments. Here’s a step-by-step guide:

1. Preparation: Start by gathering your design files in the appropriate format (e.g., SVG, EPS) and ensuring they meet the specifications required for DTF printing. This includes resolution, color mode, and mark requirements.

2. Layout Design: Utilize graphic design software to arrange your designs on the virtual DTF Transfer Gang Sheet. Place each design in its designated area, considering factors like garment type, size, and placement on the cloth. This step ensures optimal utilization of space, minimizing waste and maximizing productivity.

3. Print Settings: Configure your printer settings according to the DTF heat transfer method. Adjust temperature, pressure, and application time for accurate color reproduction and durable adhesion. Calibrating these settings precisely is crucial for consistent quality across all prints.

4. Printing: Once your layout is finalized and print settings are optimized, it’s time to print. Feed the DTF Transfer Gang Sheet into your printer, ensuring proper alignment and positioning. Initiate the print job, overseeing the process to ensure there are no errors or deviations from the set parameters.

5. Post-Print Handling: After printing, carefully remove the DTF Transfer Gang Sheet from the printer. Allow the heat transfers to cool down before peeling them away from the sheet. Inspect each transfer for quality and adhere them to the target garments according to your design plan.

DTF Transfer Gang Sheets offer a game-changing solution for rapid print turnaround. By streamlining the printing process, these sheets enhance efficiency and productivity, ensuring that your designs are transformed into tangible products in record time. In today’s fast-paced world, this technology is a testament to the innovative spirit of the industry, revolutionizing how we approach custom printing.