The DTF Heat Press, a versatile tool for custom design creation on various materials, often faces issues like temperature regulation problems, misalignment during printing, and inadequate adhesive performance. Efficient troubleshooting starts with identifying specific problems, matching symptoms to potential causes, and performing diagnostic steps such as cleaning heating plates and checking alignment. Regular maintenance, including cleaning and lubricating parts before each use, using custom sheets for even pressure distribution, and regularly inspecting the press, is crucial for enhancing its long-term performance and reliability.

Uncover the secrets to mastering your DTF Heat Press with this comprehensive guide. From frustrating glitches to optimal performance, we demystify common issues plaguing these innovative machines. Learn effective diagnostic steps to troubleshoot problems swiftly, empowering you to prevent downtime and maintain consistent results. Discover essential maintenance tips and preventive measures, ensuring your DTF Heat Press remains a reliable ally in the world of printing.

- Understanding Common DTF Heat Press Issues

- Diagnostic Steps for Effective Troubleshooting

- Preventive Measures and Maintenance Tips

Understanding Common DTF Heat Press Issues

The DTF Heat Press is a powerful tool for creating custom designs on various materials, especially in bulk DTF transfer film and DTF printing for t-shirts production processes. However, like any machinery, it’s not immune to issues. Understanding these common problems is the first step towards efficient troubleshooting. One of the frequent challenges users encounter is temperature regulation, where the heat press might fail to maintain the set temperature, leading to inconsistent print quality.

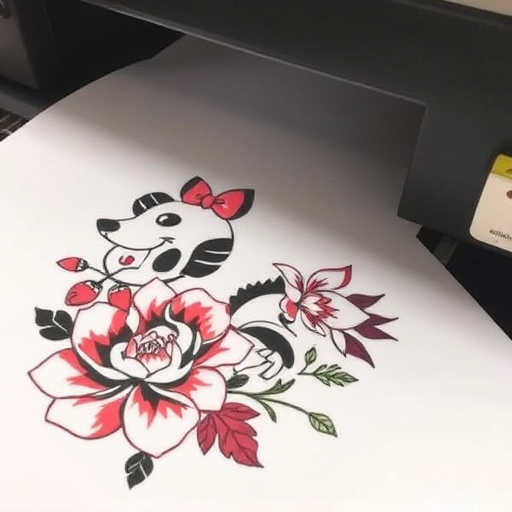

Another prevalent issue is misalignment during the printing process, causing designs to be off-center or distorted. This often occurs due to improper setup or calibration. Additionally, some users face problems with adhesive performance, such as inadequate bonding of the transfer film to the substrate, resulting in poor print transfer for bulk DTF shirt production. These issues can be addressed by regular maintenance, following manufacturer guidelines, and having a basic understanding of the machine’s functions.

Diagnostic Steps for Effective Troubleshooting

When troubleshooting issues with a DTF Heat Press, a systematic approach is key. Start by identifying specific symptoms – is there an inability to heat evenly, excessive smoke, or strange noises? Then, match these signs to potential causes, such as blocked heating elements, improper temperature settings, or misaligned press components.

Next, perform diagnostic steps accordingly. Check and clean the heating plates for any debris or residue buildup. Verify that the thermostat is functioning correctly by comparing it to known good settings. Ensure proper alignment of the press bed and platen, and check for adequate pressure application. If using a DTF for Custom graphic tees, direct to film personalized hoodies (or similar applications like dtf transfer), confirm compatibility with your specific material types and printing requirements.

Preventive Measures and Maintenance Tips

Regular maintenance is key to keeping your DTF Heat Press running smoothly and efficiently. Before each use, ensure all parts are clean and well-lubricated. This includes the platens, heating elements, and pressure mechanism. A quick wipe down with a damp cloth can remove any residual ink or debris from previous projects. Using a suitable lubricant on moving parts helps reduce friction and wear, prolonging the press’s lifespan.

Additionally, consider implementing preventive measures to avoid common issues. Always use custom sheets for heat pressing designs onto garments to ensure even pressure distribution and prevent misalignment. Regularly inspect your DTF for Apparel materials for any damage or blockages that could affect temperature control and pressure application. Staying on top of these simple maintenance routines will contribute significantly to the long-term performance and reliability of your DTF Heat Press.

In conclusion, troubleshooting common DTF Heat Press issues is a vital skill for any user aiming to optimize their printing experience. By understanding the diagnostic steps, implementing preventive measures, and adopting regular maintenance tips discussed in this article, you can significantly reduce downtime and enhance the longevity of your DTF Heat Press. Remember, a well-maintained machine ensures consistent quality and efficiency, making it an indispensable tool for professional and hobbyist printers alike.