Dyno tuning is a critical process for enhancing engine performance while ensuring safety. Using specialized equipment like dynamometers (dynos), technicians precisely adjust fuel-air mixture ratios, ignition timing, and compression pressure to prevent detonation and knock. Common enhancements include high-flow air filters and performance exhaust systems, which improve airflow and reduce backpressure. Best practices involve using high-quality fuel, maintaining consistent conditions, monitoring with diagnostic tools, and performing post-tuning maintenance checks for optimal, safe engine operation.

Dyno tuning is a powerful tool for optimizing engine performance while preventing common issues like detonation and engine knock. This article delves into these phenomena, exploring their causes and effects on vehicle health. We then highlight how dyno tuning acts as a shield, detailing techniques and tools used to mitigate these problems effectively. Furthermore, we provide best practices and benefits associated with this process, ensuring safe and efficient tuning for enhanced engine longevity.

- Understanding Detonation and Engine Knock: Causes and Effects

- The Role of Dyno Tuning in Prevention: Techniques and Tools

- Benefits and Best Practices: Ensuring Safe and Effective Dyno Tuning

Understanding Detonation and Engine Knock: Causes and Effects

Detonation and engine knock are unwanted phenomena that can significantly harm an engine’s performance and longevity. Detonation occurs when the air-fuel mixture in a cylinder is ignited at the wrong time, causing uncontrolled burning and resulting in a sharp increase in pressure. This forces the piston downward with excessive force, leading to potential damage or even destruction of critical components like pistons, valves, and cylinders. Engine knock, on the other hand, is characterized by a rhythmic pinging or knocking sound coming from the engine, usually during acceleration or high-load conditions. It’s caused by premature ignition of the air-fuel mixture, often due to a combination of factors such as incorrect fuel delivery, spark timing, or cold air intakes.

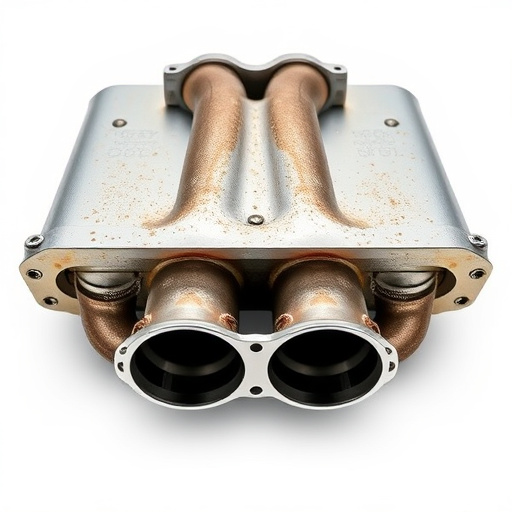

The primary consequences of detonation and knock include reduced engine power, lower fuel efficiency, and increased emissions. They can also lead to costly repairs if left unaddressed. Dyno tuning plays a crucial role in preventing these issues by meticulously adjusting various parameters such as ignition timing, fuel injection rates, and air intake systems. By optimizing these settings, dyno tuning ensures the engine operates at its peak performance while minimizing the risk of detonation. Additionally, upgrading exhaust mufflers can also contribute to better engine management by reducing backpressure and allowing for smoother combustion, further preventing knock and enhancing overall engine health.

The Role of Dyno Tuning in Prevention: Techniques and Tools

Dyno tuning plays a pivotal role in preventing detonation and engine knock by finely calibrating an engine’s performance. This process involves using specialized equipment to test and adjust various parameters, such as fuel-air mixture ratios, ignition timing, and compression pressure. By meticulously fine-tuning these aspects, dyno tuning ensures that the engine operates within optimal efficiency and safety margins.

The techniques employed include advanced scanning tools that monitor real-time data, allowing for precise adjustments to be made. Common tools include dynamometers (dynos) that measure power output, torque curves, and other metrics. Additionally, high-flow air filter kits and performance exhaust systems are often integrated into the tuning process, enhancing airflow and reducing backpressure. These components contribute to a more efficient burn cycle, thereby preventing detonation and knocking, especially under heavy load conditions.

Benefits and Best Practices: Ensuring Safe and Effective Dyno Tuning

Dyno tuning offers a safe and controlled environment to fine-tune an engine’s performance, which is particularly beneficial for preventing detonation and engine knock. By using a dynamometer (dyno), mechanics can precisely measure power outputs while making adjustments to various components in real time. This process helps identify the optimal settings for intake components, suspension components, and even brake pads, ensuring the engine operates at peak efficiency without compromising safety.

Best practices in dyno tuning involve adhering to strict protocol, including using high-quality fuel and maintaining consistent environmental conditions. Mechanics should also employ diagnostic tools to monitor engine parameters during the tuning process. Additionally, regular maintenance checks post-tuning are crucial to guarantee that all components remain in top condition, preventing any potential issues and ensuring continued optimal performance.

Dyno tuning is a powerful tool for preventing detonation and engine knock, ensuring your vehicle runs smoothly and safely. By understanding the causes of these issues and employing the right techniques with specialized tools, you can optimize engine performance while adhering to best practices. Dyno tuning offers numerous benefits, from enhanced efficiency to reduced risk of damage, making it an essential practice for anyone seeking to maximize their engine’s potential.