Oil fouling on automotive sensors is a common issue that can harm engine performance and boost maintenance costs. Dry air filters trap oil droplets and contaminants, preventing them from reaching critical sensors like oxygen sensors, mass airflow meters, and engine control units. When combined with regular oil changes and quality lubricants, dry air filters extend sensor life, improve engine efficiency, reduce the need for expensive repairs, and enhance overall vehicle performance, making them an essential component in modern vehicle maintenance routines.

Dry air filters are essential components in reducing oil fouling on sensors, a prevalent issue across various industries. This article explores the detrimental effects of oil buildup on sensor performance and how dry air filtration systems act as a robust solution. We delve into the science behind oil fouling, highlighting its impact on critical sensor functions. Additionally, we discuss the implementation of dry air filters, their numerous benefits, and why they are becoming indispensable in maintaining reliable sensor operations.

Understanding Oil Fouling on Sensors

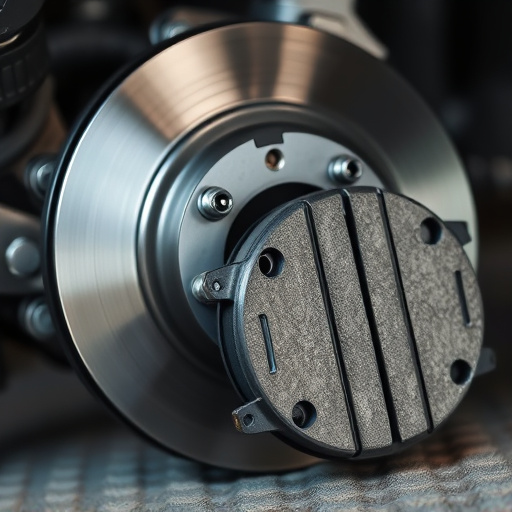

Oil fouling on sensors is a common issue that can significantly impact the performance and longevity of various automotive components. This occurs when oil from the engine’s internal combustion process accumulates on sensor surfaces, leading to misreadings and potential system malfunctions. In modern vehicles, where sensors play a critical role in monitoring and controlling engine functions, maintaining optimal sensor condition is essential for overall vehicle health.

One effective solution to prevent oil fouling is the utilization of dry air filters. These specialized filters are designed to trap microscopic particles, including oil droplets, from entering the sensitive areas of sensors. By ensuring a constant supply of clean, dry air, dry air filters minimize the risk of oil buildup on crucial components like oxygen sensors, mass airflow meters, and engine control units. Additionally, when combined with proper maintenance practices, such as regular oil changes and the use of high-quality lubricants, dry air filters contribute to the longevity of these vital sensors, ensuring optimal engine performance and reducing the need for costly repairs.

The Role of Dry Air Filters

Dry air filters play a pivotal role in enhancing vehicle performance by ensuring that only clean and dry air enters the engine. In modern vehicles, air intake systems are more complex than ever before, incorporating sensitive sensors to optimize combustion and overall efficiency. However, these sensors can be susceptible to oil fouling, which occurs when oil vapors or droplets accumulate on their surfaces, leading to reduced accuracy and potential malfunction.

A key way to mitigate this issue is by utilizing dry air filters. These specialized filters are designed to trap not only solid particulates but also moisture, preventing any water droplets from entering the air stream. By maintaining a constant flow of dry air, brake components, including sensors, remain free from oil contamination, thereby ensuring optimal vehicle performance and longevity of these critical parts.

Implementation and Benefits

Implementing a dry air filter system is a straightforward yet effective strategy to enhance vehicle performance and protect sensitive components. This technology ensures that only clean, dry air reaches the engine, sensors, and other critical parts, which is particularly crucial in modern vehicles with complex electronic systems. By removing moisture and contaminants from the air intake, it reduces the risk of oil fouling on sensors, a common issue that can lead to costly repairs.

The benefits are multifaceted. Dry air filters contribute to improved fuel efficiency as they allow for better combustion, resulting in smoother engine operation. Additionally, they extend the lifespan of various components, including coilover kits and air filter kits, by preventing premature wear and tear caused by contaminated air. This simple upgrade can be a game-changer for vehicle owners, ensuring optimal performance and peace of mind on the road.

Dry air filters play a pivotal role in mitigating oil fouling on sensors, an issue that can impede machinery performance. By ensuring a clean, dry air supply, these filters contribute significantly to maintaining sensor integrity and reliability. This is particularly crucial in industrial settings where accurate sensor readings are essential for efficient operations and safety. Implement a dry air filter system to experience enhanced equipment lifespan, reduced downtime, and improved overall operational efficiency.