Engine air intake systems are crucial for delivering clean, optimized air to internal combustion engines, enhancing performance and efficiency. Mechanics play a key role in fine-tuning these systems using techniques like modified filters and high-flow manifolds, resulting in increased horsepower, torque, and fuel efficiency. Regular maintenance and high-quality intake systems with cleanable filters prevent airflow restrictions and ensure optimal combustion for smoother driving experience and improved engine health.

Engine air intake systems play a vital role in overall engine performance. This article delves into the mechanics behind these systems, providing insights into their basic functioning and optimal management. We explore how mechanics can enhance air intake performance through strategic adjustments, addressing common issues that hinder efficiency. By understanding these principles, car owners can ensure their vehicles operate at peak levels, maximizing power and fuel efficiency. Key terms, or engine air intake, are woven naturally throughout to enhance SEO.

- Understanding Engine Air Intake Systems: The Basics

- The Role of Mechanics in Optimizing Air Intake Performance

- Common Issues and Best Practices for Effective Air Intake Management

Understanding Engine Air Intake Systems: The Basics

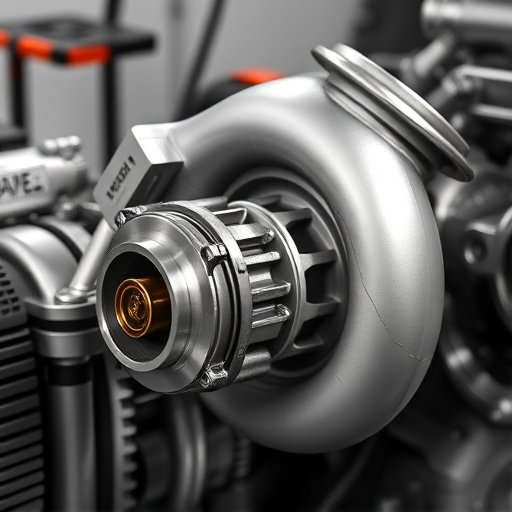

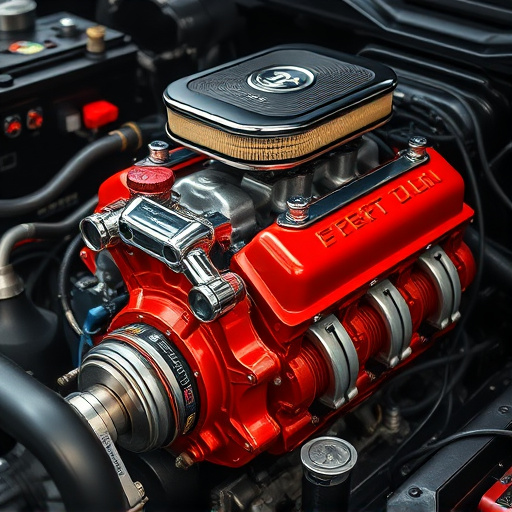

Engine air intake systems are a crucial component in any internal combustion engine, responsible for delivering the right amount of clean air to the engine for optimal performance and efficiency. At its core, an air intake system consists of several key elements: an air filter, an air box (or manifold), and various pipes or tubes that direct airflow into the engine’s cylinder head. The primary function is to draw in ambient air, filtering out contaminants like dust, dirt, and debris to ensure only clean, breathable air enters the engine.

This intricate system plays a significant role in determining the overall power and responsiveness of a vehicle. High-performance parts, such as coilover kits, rely on efficient air intake to maximize engine output. By optimizing airflow, these systems can improve horsepower and torque, providing drivers with better acceleration and overall driving pleasure. Properly designed air intake components, combined with regular maintenance, ensure that the engine receives the right mix of air and fuel for cleaner burning and reduced emissions.

The Role of Mechanics in Optimizing Air Intake Performance

In the intricate world of automotive engineering, mechanics play a pivotal role in optimizing the performance of engine air intake systems. These experts are tasked with ensuring that the right amount of clean, cold air enters an engine, which is crucial for efficient combustion and optimal vehicle performance. Mechanics employ various techniques to enhance air intake, such as modifying or replacing stock air filters, installing high-flow air intake manifolds, or even integrating cold air intakes from third-party manufacturers. By carefully considering muffler tips and other aerodynamic factors, they strive to minimize air restrictions and maximize airflow, thereby boosting engine power and fuel efficiency.

Through their meticulous work, mechanics can identify bottlenecks in the air intake system that hinder vehicle performance. They address these issues by suggesting upgrades like larger bore sizes, direct-fit cold air intakes that route cooler, denser air directly into the engine, or even reconfiguring the air box design. Such optimizations not only enhance engine output but also contribute to a smoother driving experience, making mechanics indispensable in fine-tuning engine air intake systems for peak performance.

Common Issues and Best Practices for Effective Air Intake Management

Effective engine air intake management is key to maximizing performance and fuel efficiency. Common issues include restricted airflow due to clogged or poorly designed intakes, leading to decreased power output. Intake components such as filters can accumulate dirt and debris over time, impeding airflow and reducing engine responsiveness. Additionally, improper alignment or installation of suspension kits can disrupt the flow of cold air intakes, further compromising engine performance.

To address these challenges, best practices involve regular maintenance and replacement of intake components. High-quality, well-designed air intake systems with cleanable or replaceable filters ensure unobstructed airflow. Proper suspension setup and alignment are crucial to maintaining the optimal path for cold air intakes, enhancing overall engine efficiency. These strategies, combined with a focus on seamless installation and regular checks, contribute to smoother operations and improved engine health.

Engine air intake systems are a crucial component of vehicle performance, and mechanics play a vital role in optimizing their efficiency. By understanding the basics of these systems and addressing common issues, professionals can ensure optimal airflow, leading to enhanced engine power and fuel efficiency. Effective air intake management not only improves vehicle dynamics but also contributes to overall engine longevity, making it an essential aspect for any mechanic to master.