Unusual noises from a vehicle's clutch and flywheel kit, such as grinding, chirping, or high-pitched whining, signal potential issues like worn clutch plates, misaligned gears, or bearing problems. These sounds can be linked to low fluid levels, damaged components, or recent high-performance part modifications. Prompt attention and regular maintenance are crucial for preventing premature wear, ensuring optimal performance, and diagnosing related issues affecting brakes, suspension, and other vehicle systems.

Experiencing unusual noises from your clutch and flywheel kit? Don’t panic! This comprehensive guide breaks down common sounds—clicking, grinding, whining, ticking—and reveals their potential causes. We’ll walk you through a step-by-step troubleshooting process, from inspecting worn components to ensuring proper alignment and fluid checks. Learn how regular maintenance, the right fluids, and careful driving can prevent costly repairs and keep your clutch and flywheel kit running smoothly.

- Identifying Common Clutch and Flywheel Kit Noises

- – Recognizing different noise types: clicking, grinding, whining, and ticking

- – Understanding the possible causes behind each noise

Identifying Common Clutch and Flywheel Kit Noises

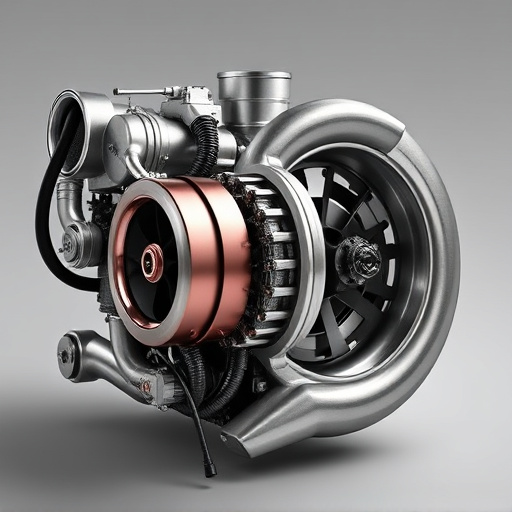

Identifying the source of unusual noises from your vehicle’s clutch and flywheel kit is a crucial first step in troubleshooting. These components play a vital role in transmitting power from the engine to the wheels, so any issues can quickly escalate. Common sounds may include grinding, chirping, or a high-pitched whining, which could indicate problems with the clutch plates, pressure plate, or flywheel itself. Grinding noises often signal worn or damaged clutch material, while chirping may be caused by misalignment or damage to the gears within the kit. A high-pitched whine could point to an issue with the bearing or a problem in the transmission system.

When addressing these noises, consider recent modifications to your vehicle. Upgrades like high-performance parts, including performance air filters and cat-back exhaust systems, can affect clutch and flywheel operation. It’s important to ensure that any aftermarket components are compatible and correctly installed to prevent unnecessary wear and noise. Regular maintenance and prompt attention to unusual sounds can help prolong the life of these critical components.

– Recognizing different noise types: clicking, grinding, whining, and ticking

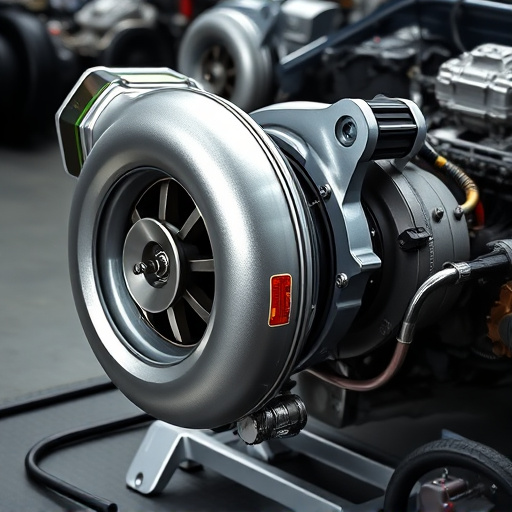

Noises from a clutch and flywheel kit can vary greatly, each with its unique characteristics that offer valuable clues to the underlying problem. Familiarizing yourself with these sounds is crucial for effective troubleshooting. One common culprit is a clicking noise, often indicating low fluid levels in the hydraulic system or worn-out pilot bearings. This sound usually occurs during clutch engagement and can be intermittent or consistent.

Next, grinding suggests issues with the clutch disc itself, possibly due to excessive wear or damage. When engaged, the grinding may get louder and could indicate a failing clutch. A whining noise, typically heard when the vehicle is in gear and accelerating, often points to problems within the flywheel or its surrounding components, such as misalignment or damaged mounting bolts. Lastly, a ticking sound might be linked to worn-out bearings or seals in the assembly. Identifying these noises can help mechanics pinpoint specific issues, enabling them to address problems related to performance brakes, high-performance parts, and even suspension components that indirectly affect clutch and flywheel functionality.

– Understanding the possible causes behind each noise

Clutch and flywheel kit noises can be a cause for concern among vehicle owners, as they may indicate potential issues with these critical components. Understanding the root causes behind each noise is essential in effective troubleshooting. One common culprit could be worn-out or damaged brake rotors, which often manifest as grinding or scraping sounds during engagement of the clutch pedal. This issue highlights the importance of regular maintenance and timely replacement of high-performance parts to ensure optimal vehicle performance.

Additionally, unusual vibrations or thumping noises may arise from an imbalance in the flywheel kit. Such symptoms could be indicative of a damaged or warped flywheel, which plays a pivotal role in transmitting power from the engine to the transmission. Given the significant impact on both drivetrain efficiency and overall vehicle performance, addressing these issues promptly is crucial.

Noises from your vehicle’s clutch and flywheel kit can be concerning, but with proper identification and understanding of their causes, you can effectively troubleshoot and address these issues. By recognizing common noise types like clicking, grinding, whining, or ticking, you’ve taken the first step towards maintaining a smooth-running transmission. Remember to consult a professional mechanic if these sounds persist, as they might indicate more serious problems. Regular maintenance and prompt action regarding any unusual noises from your clutch and flywheel kit are key to ensuring optimal vehicle performance and longevity.