DTF RIP Software is a game-changer for textile businesses, optimizing print speed, resolution, and color accuracy without compromising quality. By fine-tuning settings for resolution, color depth, and print mode, printers can significantly enhance productivity, especially in custom sheet printing. Calibrating the software involves understanding printer capabilities, regular adjustments based on usage, and configuring resolution, color depth, and media type to meet deadlines, ensure cost-effective order fulfillment, and boost customer satisfaction.

In the fast-paced world of printing, every second counts. Optimize your print speed with the right DTF RIP Software settings and unlock significant efficiency gains. This article guides you through the intricacies of DTF RIP Software, highlighting key settings to enhance printing productivity. From understanding its fundamental role in optimizing print speed to mastering calibration techniques, you’ll learn best practices to ensure top-tier performance. Elevate your printing workflow with these insights on fine-tuning your DTF RIP Software.

- Understanding DTF RIP Software and Its Role in Print Speed Optimization

- Key Settings to Enhance Printing Efficiency

- Best Practices for Calibrating Your DTF RIP Software

Understanding DTF RIP Software and Its Role in Print Speed Optimization

Understanding DTF RIP Software and Its Role in Print Speed Optimization

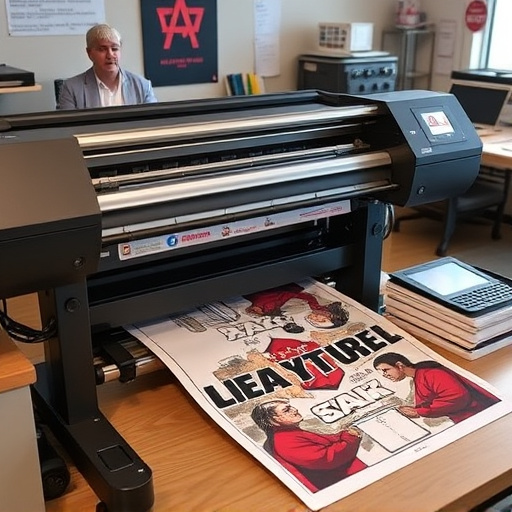

DTF (Direct-to-Film) RIP software is a critical component in optimizing print speed for textile printing businesses. RIP, or Raster Image Processing, is the technology that translates digital designs into a format suitable for printing onto various materials, including garments. By finely tuning the settings within DTF RIP software, printers can significantly enhance productivity without compromising on quality. This involves adjusting parameters related to image resolution, color profiles, and print head synchronization, among others.

Effective use of DTF RIP Software allows for faster dtf transfer film processing, which is essential for businesses dealing in custom sheets for heat pressing designs onto garments. The best dtf printer settings can dramatically reduce the time between design creation and final print output, thereby increasing throughput and meeting tight deadlines. This, in turn, enhances customer satisfaction by ensuring that orders are fulfilled promptly and efficiently.

Key Settings to Enhance Printing Efficiency

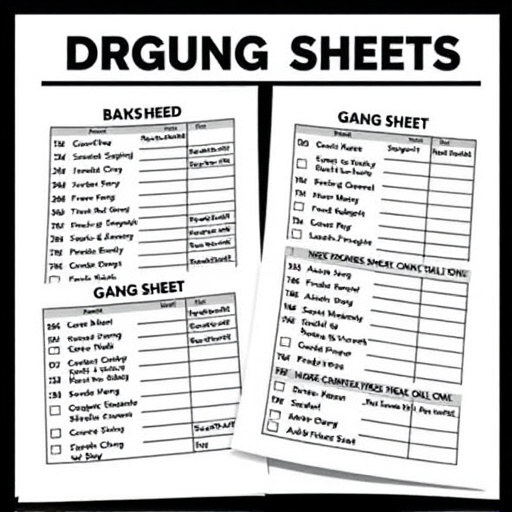

In the realm of print optimization, DTF RIP software settings play a pivotal role in enhancing efficiency, especially for businesses focusing on dtf printing, particularly for logos dft on clothing brands. The Rip (Raster Image Processing) software acts as the bridge between design and physical output, making precise adjustments to streamline the printing process. Key settings to optimize include resolution, color depth, and print mode. Increasing resolution improves detail but requires more processing power; thus, balancing quality with speed is essential.

Color depth settings determine the number of colors used in the print, directly impacting ink consumption and final image vibrancy. For dtf heat transfer paper applications, a higher color depth might be necessary to reproduce intricate designs accurately. Print mode settings also significantly affect speed; batch printing or optimizing for specific ink types can drastically reduce turnaround time without compromising quality. These adjustments collectively contribute to improving overall print efficiency, ensuring that orders are fulfilled promptly and cost-effectively.

Best Practices for Calibrating Your DTF RIP Software

Calibrating your DTF RIP software is a key step to optimize print speed and overall performance. Begin by understanding your printer’s capabilities and limitations, as different models may have unique requirements for optimal settings. Regularly checking and adjusting these settings based on usage patterns can significantly enhance efficiency. Ensure that the resolution, color depth, and media type are correctly configured for your specific dtf transfers or dtf transfer film applications.

Best practices include setting the RIP software to use the highest resolution possible without excessively increasing file sizes, optimizing color profiles for accurate reproduction, and selecting appropriate rendering methods tailored to your printing needs. Additionally, keeping the software up-to-date with the latest patches and updates ensures compatibility with advancements in printing technology, potentially leading to faster and more efficient dtf transfers.

Optimizing your DTF RIP software settings can significantly enhance print speed and overall efficiency. By understanding the key components and implementing best practices, you can harness the full potential of this technology. With the right adjustments, you’ll experience faster turnaround times, improved productivity, and better overall print quality. Remember, regular calibration ensures consistent performance, so take the time to fine-tune your software for maximum benefit.