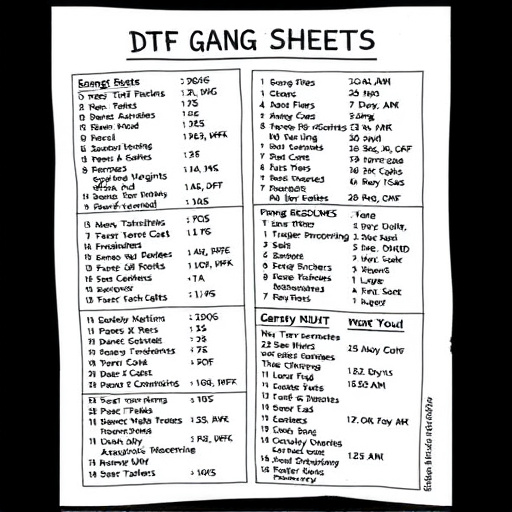

Using high-quality DTF transfer sheets significantly improves precision and efficiency in custom t-shirt printing and other applications, allowing intricate designs to be accurately replicated with vibrant colors. Their cold peel feature streamlines production, reduces time, and minimizes waste. DTF sheets offer enhanced durability, cost-effectiveness, and an eco-friendly process compared to traditional methods, enabling businesses to meet modern market demands for fast turnaround times while maintaining high-quality products.

Discover the transformative power of high-quality DTF (Direct to Film) transfer sheets. This article explores how these cutting-edge materials revolutionize printing processes, boosting precision and efficiency. From streamlining production workflows to offering cost savings and environmental benefits, DTF transfer sheets are a game-changer. Learn how their superior durability enhances longevity while minimizing waste. Uncover the key to successful digital printing, where quality sheets make all the difference.

- Enhancing Precision and Efficiency with DTF Transfer Sheets

- The Role of High-Quality Materials in Streamlining Production

- Longevity, Cost-Effectiveness, and Environmental Impact Analysis

Enhancing Precision and Efficiency with DTF Transfer Sheets

Using High-Quality DTF Transfer Sheets significantly enhances both precision and efficiency in various applications, particularly in the customization of custom t-shirts. These sheets allow for intricate design details to be transferred with remarkable accuracy, ensuring that every line, curve, and shade is precisely replicated onto the final product. This level of detail not only improves the overall aesthetics but also ensures customer satisfaction.

The efficiency gained from DTF Transfer Sheets is equally impressive. The cold peel dtf transfers feature enables quick and easy application, reducing production time considerably. Professionals can now produce high-quality custom t-shirts at a faster pace, meeting the demands of modern businesses that prioritize speed without compromising on quality.

The Role of High-Quality Materials in Streamlining Production

High-quality DTF (Direct to Film) transfer sheets play a pivotal role in streamlining production processes, especially in industries that rely on custom printing and personalized products. The materials used in these sheets significantly impact the efficiency and effectiveness of the entire manufacturing chain. Superior-grade DTF sheets ensure precise color reproduction, allowing designers and manufacturers to achieve vibrant and detailed prints on various surfaces, from textiles to ceramics.

This level of quality not only enhances the final product’s visual appeal but also speeds up production time. With robust materials, printers can effortlessly apply designs directly onto films, which then transfer accurately during the printing process. This direct-to-film approach eliminates the need for complex intermediates, reducing potential errors and minimizing waste. As a result, businesses can offer faster turnaround times for personalized items like direct to film personalized hoodies or utilize DTF printing for hoodies, catering to customers’ demands in today’s fast-paced market.

Longevity, Cost-Effectiveness, and Environmental Impact Analysis

High-quality DTF (Direct to Fabric) transfer sheets offer significant advantages in terms of longevity, making them a superior choice compared to traditional printing methods. These transfer sheets are designed to withstand various washing and drying cycles, ensuring your designs remain vibrant and intact even after multiple uses. This enhanced durability is particularly beneficial for businesses specializing in custom apparel like hoodies and T-shirts (DTF printing for hoodies), as it guarantees customer satisfaction over a prolonged period.

Moreover, DTF transfer sheets present a compelling case from an economic perspective. While initial investments may seem higher, the long-term cost-effectiveness is evident. The direct printing method reduces waste, minimizes the need for expensive equipment and supplies, and simplifies the production process. This efficiency translates to lower operational costs, making it a practical choice for businesses aiming to optimize their spending (cost-effectiveness in DTF transfer sheets). Additionally, the eco-friendly nature of DTF printing is worth noting, as it reduces water consumption and waste generation compared to traditional dye-sublimation methods, contributing to a greener production process.

High-quality DTF Transfer Sheets offer a multitude of benefits, from enhancing precision and efficiency in production to ensuring longevity and cost-effectiveness. The environmental impact of these sheets is also noteworthy, making them an eco-friendly choice. By investing in top-tier DTF Transfer Sheets, businesses can streamline their operations, reduce waste, and contribute to a more sustainable future.