The DTF Wash Test, once a cornerstone for evaluating print durability on dark fabrics, has adapted to modern digital printing methods like DTF. As the apparel industry evolves with digitalization and sustainability, this test remains critical for ensuring colorfastness and design integrity of custom garments. Despite technological advancements, it helps manufacturers maintain consumer satisfaction and brand reputation by identifying issues before product launch, especially with growing demands for vibrant, long-lasting prints in the print-on-demand era.

In 2025, amidst a rapidly evolving manufacturing landscape, the DTF (Dry, To Dry) Wash Test remains an indispensable pillar of quality assurance. As technology advances and production methods shift, understanding the enduring relevance of this traditional test method is crucial. This article explores how the DTF Wash Test ensures product reliability in a bustling market, delving into its specific benefits and real-world applications. We also predict future challenges and analyze its role in adapting to emerging trends, ensuring its longevity as an essential tool for manufacturers.

- The Evolution of Quality Assurance: Why DTF Wash Test Remains Relevant

- – Exploring the changing landscape of manufacturing and its impact on testing standards

- – Discussing advancements in technology and their effect on traditional test methods

The Evolution of Quality Assurance: Why DTF Wash Test Remains Relevant

The landscape of quality assurance has evolved significantly over the years, yet certain tests remain indispensable pillars in ensuring product excellence. The DTF Wash Test stands as a testament to this, retaining its relevance even in 2025 and beyond. Initially, this test served as a crucial gauge for evaluating the durability of prints on textiles, particularly dark fabrics, where the challenge of colorfastness is paramount.

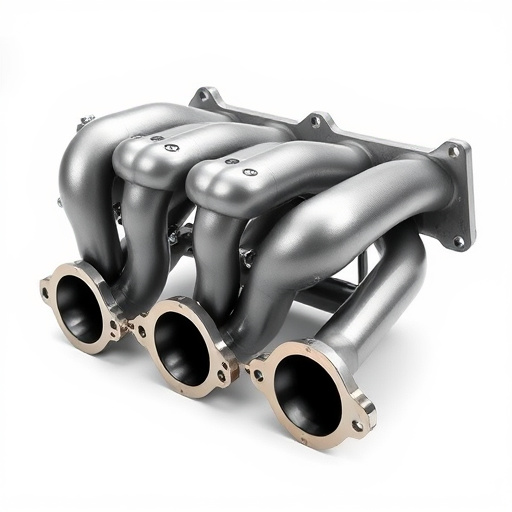

As manufacturing processes and materials have advanced, so has our understanding of consumer needs. Today, while digital printing methods like DTF (Direct to Fabric) offer unparalleled design flexibility and efficiency for dark garments, the DTF Wash Test remains a critical step in quality control. It ensures that vibrant prints not only adhere securely but also withstand repeated washing cycles, maintaining their vibrancy and integrity—a crucial factor for both manufacturers and consumers alike.

– Exploring the changing landscape of manufacturing and its impact on testing standards

The manufacturing landscape has undergone a remarkable transformation over the past decade, with technological advancements and globalization reshaping production processes globally. As we step into 2025, the shift towards digitalization, automation, and sustainable practices is more evident than ever before. This evolution has undoubtedly brought about changes in testing standards and protocols, particularly within the realm of print-on-demand (POD) manufacturing. The DTF Wash Test, once a cornerstone for ensuring product quality, now finds itself at a crossroads, where traditional methods meet modern innovations.

In this dynamic environment, the demand for customizable, high-quality garments has surged, driving the popularity of direct to fabric (DTF) printing techniques, especially for light fabrics and hoodies. DTF printing technologies offer unparalleled design versatility and efficiency, enabling manufacturers to cater to diverse consumer preferences swiftly. However, as these new printing methods gain traction, the need for rigorous testing becomes even more critical. The DTF transfer film, a key component in the process, must withstand various washes and environmental conditions without compromising colorfastness or design integrity. Thus, while embracing the advancements in manufacturing, the DTF Wash Test remains a vital tool to guarantee consumer satisfaction and brand reputation in 2025 and beyond.

– Discussing advancements in technology and their effect on traditional test methods

The evolution of technology has undoubtedly brought about significant changes in various industries, and the apparel sector is no exception. As we step into 2025, it’s fascinating to observe how advancements have impacted traditional testing methods, particularly focusing on the DTF Wash Test. While digital innovations might suggest a shift away from such conventional practices, there remains a strong case for its perseverance.

The DTF Wash Test plays a pivotal role in ensuring the durability and quality of heat-transferred designs on garments. Despite the rise of digital printing and cutting-edge DTF for Apparel techniques using dtf transfer film and custom sheets for heat pressing, this age-old test method still holds value. It provides tangible results, allowing manufacturers to identify potential issues like design fading or color bleeding before they reach the market. In an era where consumers demand long-lasting, vibrant prints on their clothing, the DTF Wash Test remains a reliable predictor of product performance, ensuring customer satisfaction and brand reputation.

Despite technological advancements, the DTF Wash Test remains a vital quality assurance method in 2025. As manufacturing processes evolve, so do material properties, making continuous testing crucial for maintaining product integrity. While newer technologies offer efficient alternatives, the DTF Wash Test’s simplicity and effectiveness in identifying potential issues cannot be overlooked. By combining traditional methods with modern innovations, manufacturers can ensure high-quality products that meet evolving market demands.