Intercooler piping is a vital automotive engineering component that optimizes airflow for improved engine performance, especially in high-performance vehicles. By promoting laminar airflow and reducing turbulence, this strategic network of tubes enhances combustion integrity and responsiveness while ensuring smooth air movement between the engine and intercooler. Advanced design and materials minimize pressure differentials and eddy currents, contributing to enhanced engine cooling efficiency, reliability, and maximum power output.

Intercooler piping, an often-overlooked component in engine systems, plays a pivotal role in enhancing overall performance. This article delves into the intricate dynamics of intercooler piping and its profound effect on airflow. By understanding how turbulence impacts engine performance, we explore the strategic design choices that minimize disruptions, ensuring smoother air flow. Discover how these innovations contribute to optimal engine efficiency, highlighting the significance of intercooler piping in modern automotive engineering.

- Understanding Intercooler Piping and its Role in Airflow Dynamics

- The Impact of Turbulence on Engine Performance

- How Intercooler Piping Design Minimizes Turbulence for Optimal Airflow

Understanding Intercooler Piping and its Role in Airflow Dynamics

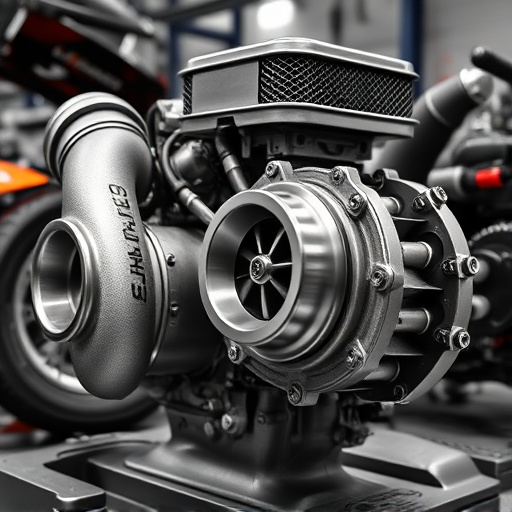

Intercooler piping plays a pivotal role in automotive engineering, specifically within air intake systems. It refers to the network of tubes and components that connect an intercooler to the engine’s air intake. This intricate system is designed to optimize airflow, ensuring smoother and more efficient coolant flow between the intercooler and the engine. By reducing turbulence, intercooler piping contributes significantly to enhancing overall engine performance, especially in high-performance vehicles.

The strategic placement and design of intercooler piping integrate seamlessly with intake components, promoting laminar airflow. This is particularly beneficial in mitigating the detrimental effects of turbulence, which can cause air to mix, leading to potential power loss. Unlike a cat back exhaust system that focuses on eliminating emissions, intercooler piping prioritizes maintaining the integrity of coolant flow, allowing for optimized combustion and enhanced engine responsiveness.

The Impact of Turbulence on Engine Performance

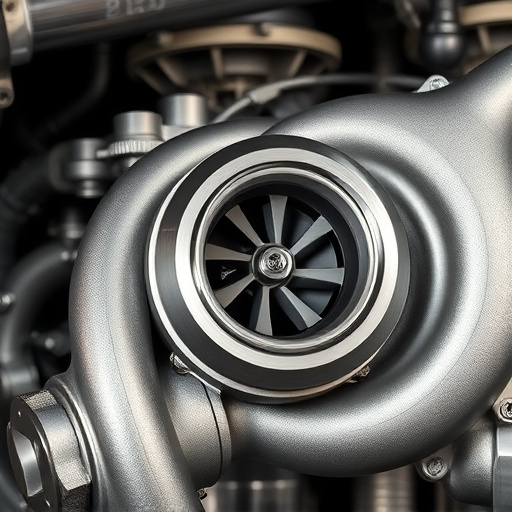

In the realm of automotive engineering, understanding airflow dynamics is key to unlocking optimal engine performance. Turbulence, a complex phenomenon, plays a significant role in this equation. When air flows through an engine, turbulent conditions can arise, leading to reduced efficiency and potential power loss. This occurs due to chaotic eddies and vortices that disrupt the smooth passage of air, causing pressure differentials and hindering the efficient combustion process. The impact is felt across various aspects of vehicle performance, from decreased horsepower to increased fuel consumption.

Intercooler piping, a strategic component in many high-performance vehicles, offers a solution to mitigate turbulence. By designing efficient cooling systems with carefully engineered piping layouts, engineers can ensure smoother airflow between the engine and intercooler. This simple yet effective approach enhances overall vehicle performance, particularly when coupled with other modifications like coilover kits and performance air filters. Such optimizations contribute to a more responsive and powerful driving experience.

How Intercooler Piping Design Minimizes Turbulence for Optimal Airflow

The design of intercooler piping plays a pivotal role in minimizing turbulence for smoother airflow within high-performance air intake systems. Strategically engineered tubing and carefully calculated bends allow for efficient air movement, ensuring that cool air reaches the engine smoothly. This meticulous design reduces eddy currents and vortices that can negatively impact performance, making it an essential component in any suspension kit aimed at enhancing power output.

Optimal intercooler piping utilizes advanced materials and manufacturing techniques to create a seamless integration with other high-performance parts. The result is a robust system that not only minimizes turbulence but also enhances overall engine cooling efficiency. This meticulous attention to detail contributes significantly to the overall performance and reliability of the vehicle, making it a crucial upgrade for those seeking maximum output from their vehicles’ engines.

Intercooler piping, with its meticulous design, plays a pivotal role in enhancing engine performance by reducing turbulence and promoting smoother airflow. By meticulously minimizing vortices and eddies, intercooler piping ensures efficient cooling, allowing engines to operate at peak efficiency. This optimal airflow is crucial for maximizing power output, improving fuel economy, and ensuring reliable engine operation, ultimately making intercooler piping design a game-changer in automotive engineering.